Copyright Notice © 2025. All rights reserved: This document and its content are protected by copyright law. Unauthorized use and/or duplication of this material without express permission from the author is strictly prohibited.

Legal Disclaimer: The information provided in this document is for general informational purposes only.

All information in the document is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability, or completeness of any information on the document. Under no circumstance shall we have any liability to you for any loss or damage of any kind incurred as a result of the use of the document or reliance on any information provided in the document. Your use of the document and your reliance on any information in the document is solely at your own risk.

This document may contain links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability, or completeness by us. We do not warrant, endorse, guarantee, or assume responsibility for the accuracy or reliability of any information offered by third-party websites linked through the document or any website or feature linked in any banner or other advertising. We will not be a party to or in any way be responsible for monitoring any transaction between you and third-party providers of products or services.

Individual results may vary, and prior success does not guarantee future success. Any financial or business decision you make is solely your responsibility. Please seek professional advice before taking any action based on the information in this document.

Key Takeaways

- Landfill gas power plants convert harmful methane emissions from decomposing waste into renewable electricity, reducing greenhouse gas impact by up to 95%.

- A typical medium-sized landfill gas facility can generate 3-5 MW of electricity, enough to power approximately 3,000-5,000 homes continuously.

- These facilities create dual environmental benefits by preventing methane release while simultaneously displacing fossil fuel energy generation.

- The technology involves a sophisticated collection system of wells, pipes, and processing equipment that transforms what was once considered waste into a valuable energy resource.

- Landfill gas projects represent one of the most cost-effective renewable energy solutions, with relatively quick returns on investment compared to other clean energy technologies.

The next time you toss something into your trash can, consider this: your discarded waste might eventually help power your home. Landfill gas to energy technology represents one of our most overlooked renewable resources, quietly transforming our waste management challenges into clean energy solutions across America and worldwide.

The Landfill Gas Website reports that these facilities have become crucial components in our transition toward a more sustainable energy future. By capturing the methane that would otherwise escape into our atmosphere, these innovative power plants deliver a one-two punch against climate change while generating reliable electricity for thousands of homes and businesses.

The Hidden Energy Source Beneath Our Waste

Every landfill contains a virtual gold mine of energy potential hiding just beneath the surface. As organic waste decomposes in the oxygen-starved environment deep within landfills, it releases a steady stream of gas – primarily methane and carbon dioxide – through a natural biological process.

This continuous gas generation can persist for 20-30 years after waste placement, creating a surprisingly long-lived energy resource that would otherwise contribute to our climate crisis.

Why Methane from Landfills Is a Climate Emergency

Methane deserves our immediate attention in the fight against climate change.

Despite being less abundant than carbon dioxide, methane packs a devastating climate punch – it's approximately 28-36 times more potent as a heat-trapping gas over a 100-year period and a shocking 84-87 times more powerful over a 20-year timeframe.

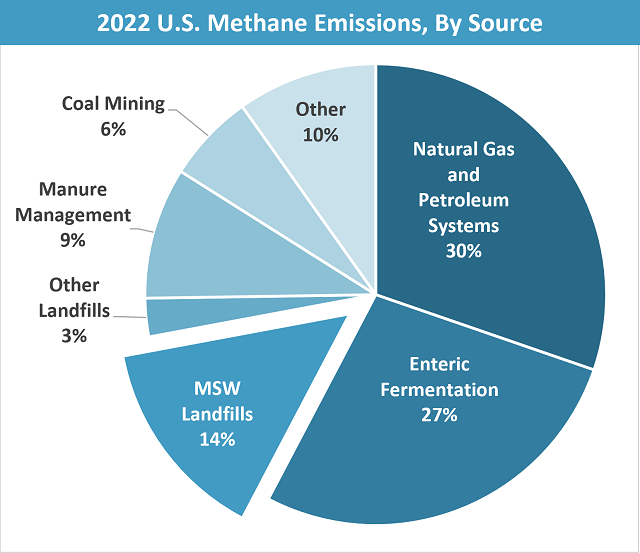

Municipal solid waste landfills represent the third-largest source of human-related methane emissions in the United States, accounting for approximately 15.1% of these emissions in 2021 according to EPA data.

When landfill gas escapes uncaptured into our atmosphere, it accelerates global warming at an alarming rate while simultaneously wasting a valuable energy resource.

“Quantifying Methane Emissions from …” from www.epa.gov and used with no modifications.

The Composition of Landfill Gas and Its Energy Potential

Landfill gas typically consists of 45-60% methane and 40-55% carbon dioxide, with trace amounts of nitrogen, oxygen, and various non-methane organic compounds. This composition varies depending on factors like waste composition, moisture content, landfill age, and temperature.

The methane component is essentially the same natural gas that powers millions of homes and businesses, just derived from waste rather than fossil fuel extraction. Each ton of municipal solid waste in a landfill can potentially generate up to 100 cubic meters of landfill gas, containing energy equivalent to about 11 gallons of gasoline.

What makes landfill gas particularly valuable as an energy resource is its predictable, continuous generation pattern. Unlike intermittent renewable sources like wind or solar, landfill gas flows 24/7, providing baseline power generation capabilities that grid operators highly value. This consistent output creates a reliable renewable energy source that complements other clean energy technologies in a diversified generation portfolio.

How Much Power Can Landfills Actually Generate?

The electricity generation potential of landfill gas facilities depends primarily on the size and age of the landfill itself. A medium-sized landfill serving a population of about 200,000 people can typically support a 3-5 megawatt power plant, generating enough electricity to power 3,000-5,000 homes continuously. The largest landfill gas facilities in the United States can generate over 40 megawatts – enough to power entire communities.

According to the EPA's Landfill Methane Outreach Program, the United States currently has over 550 operational landfill gas energy projects, collectively generating approximately 17 billion kilowatt-hours of electricity annually – equivalent to powering more than 1.5 million homes.

Yet this represents only about half of the technically feasible projects nationwide, with hundreds more landfills identified as candidates for energy recovery systems. The untapped potential remains enormous, with global estimates suggesting landfill gas could eventually provide up to 2% of total electricity needs in developed countries.

Landfill gas capture and utilisation potential over the lifetime of a landfill ihjas been shown to be no more than 50% at best.

How Landfill Gas Power Plants Work

Converting decomposing garbage into clean electricity involves a sophisticated engineering process that has been refined over decades. The transformation begins deep within the landfill and concludes with electricity flowing into the local power grid. Understanding each step reveals the ingenuity behind these renewable energy systems that operate largely out of public view.

The basic principle involves capturing naturally occurring landfill gas, removing impurities, and then combusting the methane to generate electricity through various power generation technologies. This process prevents methane from escaping into the atmosphere while simultaneously displacing fossil fuel-based electricity that would otherwise be needed.

What makes these systems particularly valuable is their ability to operate continuously regardless of weather conditions, providing reliable baseload power that complements more intermittent renewable sources.

“The Landfill Gas Expert Website” from landfill-gas.com and used with no modifications.

The Collection System: Wells, Pipes, and Blowers

At the heart of every landfill gas power plant lies an extensive collection network designed to efficiently capture the gas being generated throughout the waste mass.

Vertical wells are strategically drilled into the landfill at depths of 20-150 feet, typically spaced 100-200 feet apart to create an overlapping zone of influence. These perforated pipes allow gas to enter while preventing solid waste from clogging the system. A network of horizontal collection pipes connects these wells, creating a comprehensive gas collection web throughout the landfill.

Vacuum blowers create negative pressure throughout this piping network, actively pulling gas from the waste mass into the collection system. This carefully controlled suction must be precisely balanced – too much vacuum can draw excess air into the landfill and create conditions for underground fires, while too little fails to capture available gas.

Modern systems employ sophisticated monitoring and control systems to maintain optimal collection efficiency, typically capturing 75-85% of the total gas generated within a landfill.

“Landfill gas utilisation – Wikipedia” from en.wikipedia.org and used with no modifications.

Gas Processing and Purification Methods

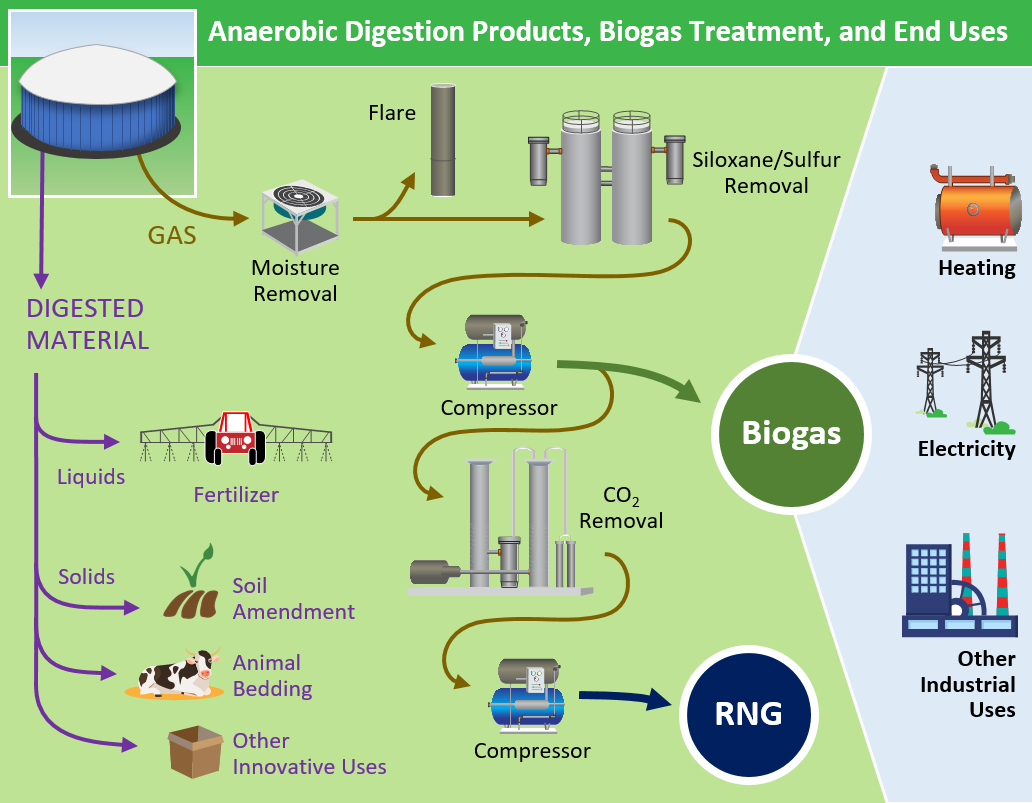

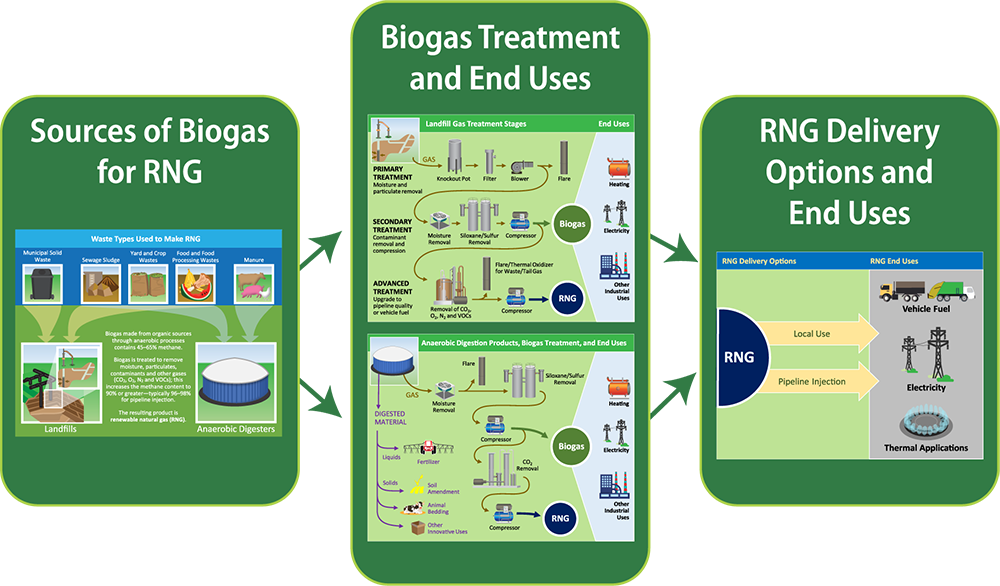

Once collected, raw landfill gas requires processing to remove moisture, particulates, and various contaminants before it can power generation equipment. The first stage typically involves a knock-out drum or moisture separator that removes condensate and particulate matter.

This is followed by a more sophisticated treatment process calibrated to the specific end-use technology. For internal combustion engines, a basic filtration system and removal of siloxanes (silicon-based compounds) is essential to prevent engine damage and excessive maintenance costs. For more information on the benefits of landfill gas energy projects, you can visit the EPA's website.

More advanced applications, such as pipeline injection or vehicle fuel production, require comprehensive purification systems that can upgrade landfill gas to near-pipeline quality natural gas.

These systems employ technologies like pressure swing adsorption, membrane separation, or cryogenic processing to achieve methane concentrations exceeding 95%. The level of required purification directly impacts project economics, with higher-purity applications demanding more capital investment but potentially yielding greater revenue streams through premium product pricing.

“The Landfill Gas Expert Website” from landfill-gas.com and used with no modifications.

4 Types of Energy Generation Technologies

Landfill gas power plants employ several proven technologies to convert methane into usable energy, each with distinct advantages depending on site-specific factors. Internal combustion engines remain the most common choice for facilities generating 1-5 MW, offering quick startup times, high efficiency at partial loads, and relatively low capital costs.

For larger facilities, gas turbines provide excellent economies of scale when generating 5+ MW, though they typically require higher gas pressures and more consistent fuel quality. For more information on capturing methane, visit our article on landfill methane capture.

Microturbines have gained popularity for smaller landfills, offering modular installation (30-250 kW units), lower emissions, and the ability to operate with lower-quality gas. Finally, fuel cells represent the cutting edge of landfill gas technology, achieving the highest electrical efficiency (up to 60%) with near-zero emissions of criteria pollutants, though their higher costs and sensitivity to gas impurities currently limit widespread adoption.

- Internal combustion engines: 1-5 MW capacity, 30-40% electrical efficiency, lower capital costs

- Gas turbines: 5+ MW capacity, 25-40% electrical efficiency, excellent for larger facilities

- Microturbines: 30-250 kW modules, 25-30% electrical efficiency, ideal for smaller sites

- Fuel cells: Modular design, up to 60% electrical efficiency, near-zero emissions but higher costs

Direct Use Applications Beyond Electricity

While electricity generation remains the most visible application for landfill gas, direct-use thermal applications often deliver superior energy efficiency and economic returns.

In these systems, minimally processed landfill gas is piped directly to a nearby facility where it replaces natural gas, propane, or other fossil fuels in boilers, kilns, furnaces, or other thermal applications. Industrial facilities located within 5 miles of a landfill can benefit from lower-cost fuel while simultaneously reducing their carbon footprint.

Some of the most successful direct-use projects include supplying landfill gas to manufacturing facilities (like brick kilns, cement plants, and paper mills), greenhouses, district heating systems, and leachate evaporation processes.

These applications typically achieve 80-90% energy efficiency compared to 30-40% for electricity generation, making them particularly attractive when a suitable end user is located near the landfill.

The highest-value application occurs when landfill gas is processed to renewable natural gas (RNG) standards and injected into natural gas pipelines or used as vehicle fuel, commanding premium prices in states with renewable fuel standards.

“Distributed Power Plants for Landfills” from www.mwm.net and used with no modifications. Flckr CC BY-NC-ND 2.0

Real-World Success Stories of Landfill Gas Projects

The theoretical benefits of landfill gas energy become tangible when examining successful implementations across diverse communities and landfill types. These projects demonstrate the adaptability of the technology to various scales, waste compositions, and local needs.

From massive facilities powering tens of thousands of homes to smaller community-focused installations, these success stories provide valuable lessons for future deployments and validate the real-world potential of this renewable energy source.

Puente Hills Facility: America's Largest Landfill Power Plant

The Puente Hills Landfill Gas-to-Energy Facility in Los Angeles County stands as a testament to what's possible at scale. Before the landfill closed to new waste in 2013, this mammoth facility generated up to 50 megawatts of electricity from 440 gas extraction wells—enough to power approximately 70,000 homes.

The $300 million facility, managed by the Los Angeles County Sanitation Districts, continues to produce declining but still significant amounts of electricity as the closed landfill gradually releases its stored gas potential.

What makes Puente Hills particularly noteworthy is its integrated approach to waste management and energy production. The facility combines gas collection with state-of-the-art generation equipment and sophisticated environmental monitoring systems.

Revenue from electricity sales—approximately $25 million annually during peak operation—helps fund continued environmental management of the closed landfill while offsetting greenhouse gas emissions equivalent to removing over 600,000 cars from the road annually.

Community-Scale Projects Making Big Impacts

While massive facilities like Puente Hills grab headlines, smaller community-scale projects often deliver more innovative approaches and deeper local benefits. The Hickory Ridge Landfill near Atlanta, Georgia demonstrates this perfectly. This closed 48-acre landfill combines a 1-megawatt landfill gas plant with an innovative solar cap—the first of its kind in the United States.

The 7,000 flexible photovoltaic panels mounted on the landfill's closure system generate an additional megawatt of solar power while the gas collection system beneath harvests methane, creating a dual-renewable energy facility.

In Sioux Falls, South Dakota, the city's landfill gas project took a different approach by focusing on direct gas use rather than electricity production. The purified landfill gas travels through a 5-mile pipeline to POET Biorefining, where it displaces natural gas used in ethanol production.

This symbiotic relationship between waste management and biofuel production creates a doubly renewable process—ethanol produced using landfill gas instead of fossil fuels—while generating over $1 million in annual revenue for the city and reducing greenhouse gas emissions by 26,000 tons yearly.

Environmental Benefits That Matter Now

The environmental case for landfill gas power plants has never been stronger. As climate scientists emphasize the critical importance of reducing methane emissions for near-term climate stability, these facilities offer an immediate, proven solution to a significant emission source.

The dual benefit of preventing potent greenhouse gas releases while simultaneously displacing fossil fuel electricity generation creates a compounding environmental advantage that few other renewable technologies can match. These benefits extend beyond climate to include improvements in local air quality, water protection, and sustainable land use.

Greenhouse Gas Reduction Numbers You Can't Ignore

The climate impact of landfill gas projects is remarkable when quantified. A typical 3-megawatt landfill gas electricity project reduces greenhouse gas emissions by approximately 34,700 metric tons of carbon dioxide equivalent annually—comparable to planting 41,000 acres of forest, eliminating emissions from 7,600 passenger vehicles, or preventing the use of 81,000 barrels of oil. These reductions occur through two distinct mechanisms: direct prevention of methane emissions and displacement of fossil fuel electricity generation.

When methane is captured and combusted in a landfill gas engine or turbine, it converts to carbon dioxide and water. While carbon dioxide is itself a greenhouse gas, it has only about 1/28th the global warming potential of methane over a 100-year period. This conversion alone reduces the climate impact of the landfill's emissions by approximately 95%.

The electricity generated then displaces power that would otherwise come from the regional grid—often from natural gas or coal plants—creating an additional layer of emission reductions.

According to EPA calculations, the 550+ operational landfill gas projects in the United States reduce greenhouse gas emissions by approximately 33 million metric tons of carbon dioxide equivalent annually—comparable to taking more than 7 million passenger vehicles off the road. Yet this represents less than half of the technically feasible projects nationwide, indicating enormous untapped potential for further climate benefits.

Emission Reduction Comparison: 3 MW Landfill Gas Project

Direct methane prevention: 25,000 metric tons CO₂e annually

Fossil fuel displacement: 9,700 metric tons CO₂e annually

Total reduction: 34,700 metric tons CO₂e annually

Equivalent to: 7,600 cars removed from roadways

“Basic Information about Landfill Gas …” from www.epa.gov and used with no modifications.

Equivalent Car Emissions Eliminated

The environmental impact of landfill gas projects becomes most relatable when expressed in terms of passenger vehicles. According to EPA calculations, a typical 3-megawatt landfill gas power plant prevents emissions equivalent to removing 7,600 cars from the road annually. This measurement helps communities and policymakers grasp the tangible climate benefits their local projects deliver, transforming abstract greenhouse gas figures into everyday equivalents everyone can understand.

This car-equivalent metric is particularly powerful when communicating with the public about project benefits. For example, the St. Landry Parish landfill project in Louisiana—serving a relatively small rural community—prevents emissions equal to 2,900 vehicles annually.

For a county with approximately 25,000 registered vehicles, this means their landfill gas project effectively eliminates the emissions impact of more than 10% of all local cars and trucks, creating a substantial local climate contribution.

Local Air Quality Improvements

Beyond greenhouse gas reductions, landfill gas projects deliver significant improvements to local air quality.

Uncontrolled landfill gas contains numerous non-methane organic compounds (NMOCs) including volatile organic compounds, hazardous air pollutants, and odorous compounds that can affect community health and quality of life. When these gases are captured and combusted in a controlled energy recovery system, these compounds are destroyed with destruction efficiencies typically exceeding 98%.

Modern landfill gas energy facilities employ advanced emission control technologies that ensure criteria pollutants remain well below regulatory thresholds.

The controlled combustion process virtually eliminates the intermittent odors that often trigger community complaints about landfills while reducing concentrations of potentially harmful compounds in the surrounding airshed.

For communities that have implemented these projects, the improvement in local air quality often becomes one of the most immediately noticeable benefits. For more information on how landfill gas is used as a sustainable energy source, explore this landfill gas to energy guide.

Economic Advantages of Landfill Gas Energy

While the environmental benefits of landfill gas projects are compelling, their long-term sustainability ultimately depends on solid economics. Fortunately, these facilities typically deliver robust financial returns alongside their climate advantages.

The revenue streams, job creation, and energy price stability they offer create a powerful economic case that complements their environmental benefits, helping explain why hundreds of communities and private operators have embraced this technology.

Revenue Streams for Municipalities and Waste Companies

Landfill gas projects create multiple revenue opportunities from what was once considered merely a compliance cost. Electricity sales represent the most common income source, with power purchase agreements typically ranging from $0.04-$0.08 per kilowatt-hour depending on local markets and renewable energy incentives. A 3-megawatt facility generating 24,000 megawatt-hours annually can produce $960,000-$1,920,000 in yearly electricity revenue.

Beyond electricity sales, projects may qualify for renewable energy credits, carbon offset credits, renewable fuel credits (for pipeline or vehicle fuel projects), and various tax incentives that significantly enhance financial returns.

The tax credits available through the Inflation Reduction Act have been particularly transformative, allowing many previously marginal projects to achieve attractive returns. For publicly owned landfills, these new revenue streams help fund essential services without increasing local taxes, creating a financial win for the entire community.

![]()

“Landfill Gas Market Size, Growth …” from www.fortunebusinessinsights.com and used with no modifications.

Job Creation in Green Energy Sectors

Landfill gas projects generate significant employment throughout their lifecycle, from initial construction through decades of operation. A typical 3-megawatt project creates approximately 5-7 full-time equivalent positions during construction and 2-3 permanent operations and maintenance jobs.

While these numbers might seem modest for individual projects, the nationwide impact is substantial—the EPA estimates that existing landfill gas energy projects have created more than 9,000 jobs across the United States.

The employment benefits extend beyond direct jobs to include manufacturing positions producing specialized equipment, engineering and environmental consulting roles, and various supporting service providers.

These positions typically offer above-average wages and develop technical skills transferable to other renewable energy and environmental sectors. As the industry continues to grow, particularly with the expansion into renewable natural gas production, the employment benefits will likely accelerate.

Energy Price Stability for Local Communities

One of the most valuable yet often overlooked economic benefits of landfill gas energy is the price stability it provides. Unlike fossil fuel sources subject to global market volatility, landfill gas production costs remain remarkably stable over time.

When municipalities use this energy to power their own operations—such as wastewater treatment plants, administrative buildings, or vehicle fleets—they effectively lock in energy costs for decades, creating budgetary predictability that facilitates long-term planning.

Communities like Jackson County, Michigan demonstrate this advantage perfectly. Their landfill gas project supplies energy to both their resource recovery facility and their wastewater treatment plant, reducing county energy expenditures by over $450,000 annually while insulating these essential services from market price fluctuations.

As climate policies and geopolitical factors continue to impact traditional energy markets, this price stability benefit becomes increasingly valuable to local governments and businesses.

Starting a Landfill Gas Project: Steps to Success

Converting the potential of landfill gas into a successful energy project requires careful planning, appropriate technology selection, and strategic partnerships.

Whether you're a municipal waste manager, a renewable energy developer, or a sustainability professional, understanding the essential steps and potential pitfalls can make the difference between a thriving facility and a disappointing outcome. The good news is that hundreds of successful projects have created a well-established development pathway that new projects can follow.

Feasibility Assessment: Is Your Landfill Suitable?

Not every landfill makes a good candidate for energy recovery. The initial feasibility assessment should evaluate several critical factors, beginning with gas quantity and quality.

Generally, landfills containing at least one million tons of waste with a depth exceeding 40 feet produce sufficient gas for energy recovery. The waste composition matters significantly—landfills with higher proportions of organic waste generate more methane, while construction and demolition waste produces considerably less.

Beyond gas production, successful projects require appropriate infrastructure accessibility including proximity to the electrical grid or natural gas pipelines, reasonable interconnection costs, and suitable land availability for the energy plant.

The US regulatory environment plays a crucial role too—states with renewable portfolio standards, favourable net metering policies, or specific landfill gas incentives create much more favourable economics. The EPA's Landfill Methane Outreach Program offers free preliminary feasibility assessments that help landfill operators determine if their site merits further investigation.

“Landfill Gas Market Size, Share and …” from www.factmr.com and used with no modifications.

Funding Options and Financial Incentives

Landfill gas projects typically require $2-3 million in capital investment per megawatt of generating capacity, with economics heavily influenced by available incentives and financing mechanisms.

The recent expansion of federal tax credits in the US through the Inflation Reduction Act has dramatically improved project economics, offering up to 30% investment tax credits or $35 per megawatt-hour production tax credits for qualifying facilities. For public entities that cannot directly utilize tax credits, transferability provisions now allow them to monetize these benefits through partnerships with tax-paying entities.

Beyond tax incentives, funding sources include municipal bonds, private equity, equipment leasing arrangements, and various state-level grant programs specifically targeting renewable energy or methane reduction.

Some developers offer build-own-operate models that require zero upfront capital from the landfill owner in exchange for a share of project revenues or a fixed lease payment. The optimal financing structure depends on project scale, ownership structure, and risk tolerance, with most successful projects utilizing a combination of funding mechanisms to maximize returns.

“Breaking Down Clean Energy Funding in …” from decarbonization.visualcapitalist.com and used with no modifications.

Regulatory Requirements and Permits

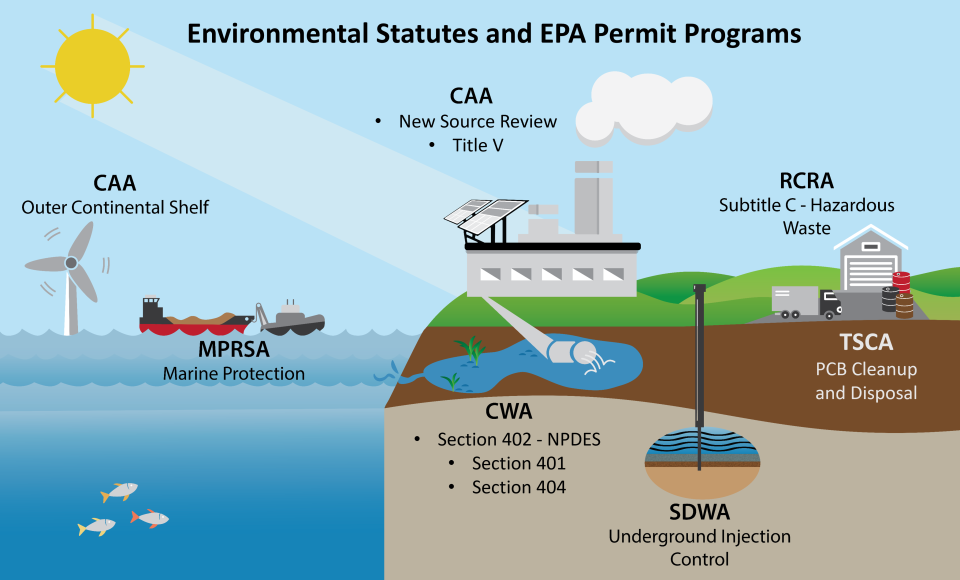

Navigating the regulatory landscape represents one of the most challenging aspects of landfill gas project development. At minimum, projects typically require air quality permits (often a Title V operating permit), construction permits, zoning approvals, and compliance with

New Source Performance Standards for landfills. Projects connecting to the electrical grid must navigate interconnection agreements with local utilities, which can involve complex technical requirements and occasionally substantial grid upgrade costs.

The permitting timeline often becomes the critical path for project development, frequently requiring 12-18 months from initial application to final approval.

Successful developers typically engage regulatory agencies early in the process, often during the feasibility stage, to identify potential compliance challenges before significant resources are committed. Experienced environmental consultants with specific landfill gas permitting experience can significantly streamline this process, helping avoid costly delays and ensuring all regulatory requirements are properly addressed.

“About EPA Permitting | US EPA” from www.epa.gov and used with no modifications.

Finding the Right Technology Partners

Selecting appropriate technology partners dramatically impacts both construction costs and long-term operational success. The specialized nature of landfill gas equipment—designed to handle variable gas quality, siloxane contaminants, and other unique challenges—makes vendor experience particularly crucial. The most successful projects typically involve technology providers with extensive landfill gas-specific experience rather than general power generation equipment adapted to this application.

Beyond equipment selection, operational expertise significantly influences project outcomes. Some landfill operators choose to manage energy facilities themselves, but many find that specialized third-party operators deliver superior performance, particularly for larger or more complex systems.

These operators bring specialized knowledge about engine tuning for landfill gas applications, predictive maintenance approaches that maximize uptime, and troubleshooting skills for the unique challenges these systems present. The ideal partnership structure depends on the landfill operator's internal capabilities, risk tolerance, and long-term objectives.

Challenges and Solutions in Landfill Gas Energy

Despite their compelling benefits, landfill gas energy projects face several significant challenges that must be addressed for successful implementation. Understanding these obstacles—and the proven solutions developed by industry leaders—helps new projects avoid common pitfalls that can undermine performance or financial returns.

With hundreds of operational projects nationwide, the industry has developed effective approaches to overcome these challenges while continuously improving technology and operational practices.

Dealing with Variable Gas Quality

Perhaps the most persistent operational challenge involves managing the inherently variable composition of landfill gas. Unlike natural gas with its relatively consistent methane content, landfill gas fluctuates based on waste composition, seasonal temperature changes, precipitation levels, and landfill age. Methane concentrations typically range from 45-60%, with corresponding variations in energy content that can impact generation equipment performance.

Modern facilities address this challenge through sophisticated gas monitoring systems that continuously analyse composition and adjust equipment parameters accordingly. Advanced control systems can modulate engine timing, air-fuel ratios, and other operating parameters to maintain efficient combustion despite gas variations. For more severely fluctuating gas streams, blending systems can incorporate propane or natural gas during low-methane periods to maintain consistent energy content, though this approach reduces the renewable percentage of the facility's output.

Overcoming Public Perception Issues

Public misconceptions about landfill gas facilities sometimes create community opposition that can delay or derail otherwise viable projects. Common concerns include fears about increased truck traffic, noise, air emissions, or the perception that energy recovery somehow encourages more waste generation. Proactive community engagement represents the most effective solution, beginning with transparent communication about project benefits, emissions controls, and operational safeguards well before permit applications are submitted.

Successful developers often organize tours of operational facilities for community leaders and concerned citizens, provide clear comparisons between controlled gas combustion versus flaring or venting alternatives, and emphasize local economic benefits including job creation and revenue generation. Educational partnerships with local schools and colleges can further build community support while developing workforce pathways for future employment. When properly implemented, these engagement strategies transform potential opposition into community pride around local renewable energy production.

“Renewable Natural Gas | US EPA” from www.epa.gov and used with no modifications.

Technical Limitations and Maintenance Needs

Landfill gas contains various contaminants that create unique maintenance challenges for energy systems. Siloxanes—silicon compounds from personal care products and certain industrial materials—are particularly problematic, forming abrasive silicon dioxide deposits inside combustion chambers when burned. Hydrogen sulphide creates corrosive conditions in engines and exhaust systems, while moisture variations affect combustion stability and system efficiency.

Addressing these challenges requires specialized maintenance protocols, typically including more frequent oil changes, cylinder head rebuilds, and catalyst replacements than comparable natural gas equipment would require.

Advanced gas treatment systems incorporating multiple filtration stages, refrigeration to remove moisture, activated carbon for siloxane removal, and chemical scrubbing for hydrogen sulphide can significantly reduce these maintenance requirements, though they add capital and operational costs. The economic optimization involves balancing treatment system costs against reduced maintenance expenses and improved equipment longevity.

The Future of Waste-to-Energy Is Bright

The landfill gas energy sector stands at an inflection point, with technological advances, supportive policies, and growing climate urgency creating unprecedented momentum.

While capturing methane from existing landfills remains essential, the industry is simultaneously evolving toward more comprehensive waste-to-energy approaches that maximize resource recovery across the entire waste management lifecycle. This evolution presents exciting opportunities for communities, energy developers, and waste management professionals to collaborate on increasingly sophisticated and beneficial projects.

The most transformative trend involves the rapid growth of renewable natural gas (RNG) production from landfill gas. By purifying landfill gas to pipeline quality standards (95%+ methane), these projects can inject renewable gas directly into natural gas distribution systems or use it as vehicle fuel.

RNG commands premium prices in transportation markets due to renewable fuel standards, particularly in California where credits can exceed $30 per million BTU—often tripling project revenues compared to electricity generation. This economic driver is shifting new project development increasingly toward RNG, with the National Renewable Energy Laboratory projecting that landfill-derived RNG could replace up to 10% of current diesel consumption in the transportation sector.

“Renewable Natural Gas | US EPA” from www.epa.gov and used with no modifications.

Frequently Asked Questions

- How do landfill gas power plants compare to other renewable energy sources?

- What happens to landfill gas that isn't captured?

- Can landfill gas be used directly in homes like natural gas?

- How long does a typical landfill produce usable gas?

- Are there environmental risks associated with landfill gas projects?

Landfill gas power plants offer unique advantages compared to other renewables. Unlike wind and solar generation, they provide consistent baseload power regardless of weather conditions or time of day. Their predictable output helps stabilize electrical grids increasingly dominated by intermittent renewables, making them valuable complementary resources in a diverse clean energy portfolio. While their total generation potential is smaller than wind or solar, their reliability and dispatchability give them disproportionate grid value.

The primary environmental risk in landfill gas systems involves potential leakage from collection systems, which sophisticated monitoring equipment and regular inspections effectively mitigate. Modern facilities employ continuous emission monitoring systems that verify destruction efficiency and ensure compliance with stringent air quality standards. When properly designed and operated, these facilities maintain emission levels far below regulatory requirements while preventing the much larger environmental impact of uncaptured methane release.

While landfill gas could theoretically heat homes directly, practical considerations make this application rare. The infrastructure costs of distributing minimally processed landfill gas to residential areas would be prohibitive, and variation in gas composition could create safety concerns in residential appliances designed for consistent natural gas.

However, when processed to renewable natural gas standards through additional purification, landfill-derived gas becomes indistinguishable from conventional natural gas and can safely serve all the same applications through existing natural gas infrastructure.

“Landfill gas utilization – Wikipedia” from en.wikipedia.org and used with no modifications.

How long can a landfill produce usable gas for energy?

Landfill gas production follows a relatively predictable curve, beginning shortly after waste placement and continuing for decades. Gas generation typically peaks 5-7 years after waste placement, then gradually declines over the following 20-30 years.

Most energy projects maintain economic viability for 15-20 years, after which declining gas production may require equipment downsizing or conversion to flaring for remaining emissions. Larger landfills with ongoing waste acceptance can sustain energy production much longer by continually adding new gas sources as older sections decline.

Several factors influence gas longevity including waste composition, moisture levels, and climate conditions. Landfills in wetter regions typically produce gas more quickly but for shorter durations compared to arid regions where decomposition proceeds more slowly.

Modern landfill designs incorporating leachate recirculation can accelerate and potentially extend gas production by maintaining optimal moisture conditions for microbial activity. Some facilities even implement strategic water addition in closed sections specifically to enhance gas production for energy recovery.

Are landfill gas power plants noisy or smelly for nearby residents?

Modern landfill gas facilities incorporate extensive noise mitigation and odor control systems that minimize community impacts. Generation equipment is typically housed in sound-attenuated buildings designed to maintain noise levels below 65 decibels at property boundaries—comparable to normal conversation levels. Exhaust systems include industrial-grade silencers, while cooling systems employ low-noise fan technologies to further reduce sound transmission.

Typical Noise Levels from Landfill Gas Facilities

Inside engine building (unmitigated): 95-105 dB

Inside engine building (with controls): 80-85 dB

At facility boundary (300 ft): 55-65 dB

At nearest residence (1,000+ ft): Below ambient backgroundTo learn more about the benefits of utilizing landfill gas, explore how landfill gas to energy can be a win-win energy source.

Regarding odours, landfill gas systems actually improve local conditions by capturing and combusting the same gases that would otherwise cause landfill odours. The collection system maintains negative pressure within the waste mass, preventing fugitive emissions that could create nuisance odours.

In the uncommon event of system shutdown, modern facilities automatically direct gas to enclosed flares that achieve 98%+ destruction efficiency for odorous compounds, maintaining continuous odour control even when not generating energy.

Properly designed facilities with appropriate buffer distances pose virtually no nuisance concerns for neighbouring properties. Most regulatory frameworks require setbacks of 500-1,000 feet from residences, though actual impacts typically become undetectable at much shorter distances.

Community complaints about properly operated facilities are exceedingly rare, with most neighbours unaware of daily operations beyond seeing the facility building itself. For more information on safety measures, check out this article on landfill gas monitoring.

How much does it cost to build a typical landfill gas power plant?

Capital costs for landfill gas electricity projects typically range from $2-3 million per megawatt of installed capacity, with economies of scale favouring larger installations. This includes gas collection infrastructure, treatment systems, generation equipment, interconnection costs, and associated engineering and permitting expenses.

Renewable natural gas (RNG) projects involve significantly higher investments—typically $9-15 million for a moderate-sized facility producing 1,000 MMBtu daily—due to the sophisticated gas upgrading equipment required to achieve pipeline quality standards.

Operating costs generally range from $200-300 per kilowatt of capacity annually for electricity projects, covering maintenance, labour, consumables, and periodic engine rebuilds. RNG facilities face higher operating expenses of approximately $2-4 per MMBtu produced, primarily for power consumption in gas compression and purification processes.

Despite these costs, project economics remain favourable in supportive regulatory environments, with electricity projects typically achieving simple payback periods of 5-8 years and RNG projects potentially recouping investments in as little as 3-5 years when renewable fuel credits are monetized.

Can small landfills also generate electricity profitably?

Historically, economically viable landfill gas electricity projects required minimum capacities of 800-1,000 kilowatts, limiting opportunities for smaller landfills.

However, technological advances have dramatically expanded options for smaller sites. Microturbines available in modules as small as 30 kilowatts allow right-sized installations for landfills previously considered too small for energy recovery. These systems offer proportionally higher capital costs but require less maintenance expertise and can operate efficiently at varying output levels as gas production changes.

For very small landfills, direct-use applications often provide better economics than electricity generation. Projects supplying landfill gas directly to neighbouring facilities for boiler fuel, process heating, or leachate evaporation can be viable with gas flows supporting as little as 300-500 kilowatts of thermal energy.

The simplicity of these systems—requiring minimal gas treatment and avoiding electrical interconnection complexities—makes them particularly suitable for smaller operations with limited resources and expertise.

What happens to landfill gas if it's not captured for energy?

Federal regulations require larger landfills to collect and control landfill gas regardless of whether it's used for energy. In facilities without energy recovery, this gas is typically destroyed in a flare—a controlled combustion device that converts methane to carbon dioxide and water.

While flaring achieves the primary environmental benefit of reducing methane emissions, it wastes the energy resource that could otherwise displace fossil fuel consumption, essentially burning a renewable fuel without capturing its value.

For smaller landfills exempt from gas collection requirements, uncaptured methane simply escapes into the atmosphere where it contributes significantly to climate change. These fugitive emissions can also create local odour problems, potential safety hazards from migrating gas, and contribute to ground-level ozone formation through interactions between methane and other atmospheric compounds.

Energy recovery systems transform this environmental liability into a valuable resource while providing superior environmental performance compared to minimal regulatory compliance approaches.

Landfill gas power plants represent one of our most practical and immediately available tools for simultaneously addressing waste management challenges, energy needs, and climate goals. As we continue advancing toward a more sustainable future, these facilities demonstrate how innovative approaches can transform what was once considered waste into a valuable community resource.

Visit the Landfill Gas Website to learn more about how communities nationwide are harnessing the power beneath their waste.

About Us

Steve Last, Chartered Waste Manager (MICWM), brings over 30 years of expert consulting experience to the waste management, anaerobic digestion, and renewable energy sectors through IPPTS Associates.

Specialising in biogas, landfill gas, depackaging equipment, and innovative sustainable solutions, Steve supports businesses and regulators in navigating complex environmental compliance and operational efficiency.

Discover how IPPTS Associates can elevate your waste management and renewable energy strategies—visit ipptsassociates.co.uk today!

Other IPPTS Associates websites include www.landfill-gas.com and www.anaerobic-digestion.com.

Best Portable Landfill Gas Analyzer Reviews & Comparison

Landfill gas monitoring is critical for health, safety, and compliance. A top-notch portable analyzer detects harmful gases in real-time, safeguarding workers and the environment. As regulations tighten, reliable equipment becomes essential for avoiding fines and mitigating risks associated with gas emissions from decomposing waste…

Methane Emissions from Landfills: Problems and Solutions

Methane emissions from landfills significantly contribute to climate change due to their potent greenhouse effect. Capturing and utilizing landfill gas as energy, reducing organic waste, and enhancing recycling are vital solutions. Community engagement and effective policy regulations are key to mitigating these emissions and tackling global warming effectively…

Landfill Gas Pin Wells: A Low-Cost, High-Impact LFG Extraction Option

Discover the advantages of landfill gas pin wells, a cost-effective solution for efficient LFG extraction. Easier installation, lower costs, and increased gas capture make them ideal for sustainability. Learn how pin wells transform waste into energy, reducing emissions and supporting renewable projects across waste management facilities…

Why Do Landfill Gas Monitoring in Soil, the Air, Near the Surface, & In Confined Spaces

Landfill gas monitoring is critical for preventing health risks and hazards near landfill sites. Detecting gases like methane, which is flammable and a climate change contributor, is essential. Effective monitoring employs soil, air, and emissions techniques to ensure safety and environmental protection…