Landfill gas flares are systems used to burn off methane and other gases produced during the decomposition of waste in landfills, minimizing climate impact. These flares are crucial for controlling odors, preventing explosions, and reducing greenhouse gas emissions. By oxidizing the methane (a potent greenhouse gas) into less harmful carbon dioxide and water vapour, flares minimize the environmental impact of landfill gas.

Key Takeaways

- Landfill flare systems are critical for converting harmful methane gas into less potent carbon dioxide, reducing greenhouse impact by over 95%.

- Enclosed flare systems offer superior destruction efficiency (up to 99.9%) compared to open flares, though they come with higher installation and maintenance costs.

- Proper gas collection networks featuring strategically placed wells and efficient piping are essential for maximizing capture and preventing fugitive emissions.

- EPA regulations mandate specific destruction efficiencies and monitoring protocols for landfills exceeding certain emission thresholds.

- Regular maintenance and performance monitoring of flare systems are crucial for regulatory compliance and optimal environmental protection.

Proper management of landfill gas represents one of the most significant opportunities for reducing harmful emissions while ensuring regulatory compliance. As organic waste decomposes in landfills, it generates a mixture of gases dominated by methane and carbon dioxide – both potent greenhouse gases with substantial environmental impacts. Implementing effective flare systems transforms this environmental liability into a manageable output, dramatically reducing both climate impacts and local health concerns.

![A landfill collection system shown in 3D cut-away style. By US EPA - LMOP (US EPA - LMOP) [Public domain], via Wikimedia Commons. A landfill collection system shown in 3D cut-away style. By US EPA - LMOP (US EPA - LMOP) [Public domain], via Wikimedia Commons.](https://landfill-gas.com/wp-content/uploads/2018/11/512px-Landfill_gas_collection_system.jpg)

“Landfill gas – Wikipedia” from en.wikipedia.org and used with no modifications.

Why Landfill Gas Demands Serious Attention

Landfill gas management isn't just an environmental checkbox—it's a critical component of responsible waste management that affects community health, safety, and regulatory standing. When organic materials decompose in the oxygen-deprived environment of landfills, they produce a gas mixture typically containing 50% methane and 50% carbon dioxide, along with trace amounts of non-methane organic compounds (NMOCs). Left uncaptured, these gases contribute significantly to greenhouse effects while creating explosion risks and potential health hazards for surrounding communities.

Methane's Powerful Impact on Climate Change

Methane demands immediate attention due to its extraordinary potency as a greenhouse gas. Though it remains in the atmosphere for a shorter period than carbon dioxide, methane traps heat 28-36 times more effectively over a 100-year period. This makes landfills—responsible for approximately 14.5% of all human-related methane emissions in the United States—prime targets for emissions reduction strategies. By capturing and combusting methane through properly designed flare systems, landfill operators can dramatically reduce their climate impact, effectively converting methane to carbon dioxide which, while still a greenhouse gas, is significantly less potent. This single conversion process reduces the warming potential of landfill emissions by over 95%.

Health and Safety Risks from Uncontrolled Gas

Beyond climate implications, uncontrolled landfill gas presents immediate risks to human health and safety. Methane creates explosion hazards when allowed to accumulate in confined spaces, with concentrations between 5-15% by volume being potentially explosive. Landfill gas also contains various volatile organic compounds (VOCs) and hazardous air pollutants that can trigger respiratory issues, headaches, and other health concerns in nearby populations. Hydrogen sulfide, often present in landfill gas, produces the characteristic “rotten egg” odor that generates complaints from neighboring communities. Additionally, long-term exposure to certain NMOCs has been linked to more serious health concerns including liver damage and increased cancer risks.

The migration of landfill gas through soil presents another significant concern, as it can damage vegetation by displacing oxygen in the root zone and potentially enter nearby structures. Gas control systems featuring properly designed collection networks and flares effectively mitigate these risks, protecting both facility workers and surrounding communities from harmful exposure while preventing the dangerous accumulation of explosive gases.

“Lo-Cal Flare Range – Ennovo Equipment” from ennovo.com.au and used with no modifications.

EPA Regulations for Landfill Emissions

The Environmental Protection Agency has established comprehensive regulations governing landfill gas management through the New Source Performance Standards (NSPS) and Emission Guidelines. These regulations require municipal solid waste landfills exceeding specific thresholds to implement gas collection and control systems. For landfills with design capacities exceeding 2.5 million metric tons and emissions above 34 metric tons of NMOC annually, gas collection and destruction become mandatory. Regulatory requirements specify minimum destruction efficiencies (typically 98%) and mandate continuous monitoring of temperature, flow rates, and other operational parameters. Recent regulatory updates have lowered emissions thresholds, bringing more facilities under compliance requirements and emphasizing the growing importance of effective gas management strategies.

How Flare Systems Transform Harmful Gas into Safe Emissions

Flare systems serve as the primary technology for destroying harmful components in landfill gas while converting methane to less potent compounds. These engineered combustion systems operate on a relatively simple principle: they burn collected landfill gas at high temperatures, transforming methane into carbon dioxide and water vapor while destroying most non-methane organic compounds. This transformation significantly reduces both greenhouse impacts and the concentration of potentially harmful substances before gases are released to the atmosphere.

The Chemistry Behind Methane Combustion

The core function of a landfill gas flare system hinges on a fundamental chemical reaction: CH₄ + 2O₂ → CO₂ + 2H₂O. This reaction converts methane (CH₄) and oxygen to carbon dioxide and water vapor when sufficient temperature and residence time are achieved. Effective combustion requires temperatures exceeding 1,500°F (816°C) and sufficient residence time—typically 0.3-1.0 seconds—to ensure complete destruction of methane and other organic compounds. Proper air-to-fuel ratios must be maintained to achieve optimal combustion, with most systems operating at 5-7% excess oxygen. The stoichiometric balance is critical; too little oxygen results in incomplete combustion and higher emissions, while excessive air dilutes the exhaust and can potentially extinguish the flame.

Modern flare systems incorporate sophisticated controls to maintain these parameters despite variations in gas flow and composition. Temperature sensors, flow meters, and automated air control systems work together to ensure consistent, complete combustion across varying operational conditions. Some advanced systems even adjust burner configurations in real-time to accommodate changing gas quality, ensuring optimal destruction efficiency regardless of fluctuations in the landfill gas stream.

Destruction Efficiency: Converting Methane to CO₂

The effectiveness of a flare system is measured primarily by its destruction and removal efficiency (DRE)—the percentage of methane and NMOCs successfully combusted. Modern enclosed flare systems regularly achieve DREs of 98-99.9%, effectively eliminating nearly all methane and dramatically reducing the concentration of other pollutants. This high-efficiency conversion process transforms landfill gas from an environmental liability into a managed emission that meets regulatory standards. Performance testing typically involves stack testing to measure actual destruction rates, with continuous parametric monitoring ensuring ongoing compliance between formal test periods.

Typical Destruction Efficiencies by Flare Type

Open Flare: 95-98%

Enclosed Flare: 98-99.9%

Ground Flare: 98-99.5%

Note: Actual performance depends on proper sizing, maintenance, and operational controls

Types of Landfill Gas Flare Systems

Selecting the appropriate flare system for your landfill operation requires understanding the fundamental differences between available technologies. Each system presents distinct advantages, limitations, and operational characteristics that must be carefully evaluated against your specific site conditions, gas characteristics, and regulatory requirements. The right choice balances destruction efficiency, capital costs, operational complexity, and long-term maintenance considerations.

Landfill operators can choose from several established flare technologies, each designed to address different operational priorities. The selection process must consider not only current conditions but also anticipate how gas generation rates and composition will evolve throughout the landfill's active and post-closure periods.

Open Flares: Simple but Effective Solutions

Open flares, sometimes called candlestick or elevated flares, represent the most straightforward approach to landfill gas combustion. These systems feature an elevated pipe with a burner assembly at the top, where gas is combusted in the open air without an enclosure. The visible flame burns freely, providing visual confirmation of operation but limiting temperature control and combustion optimization. Their relatively simple design offers lower capital costs and easier maintenance compared to enclosed alternatives, making them appropriate for smaller landfills or temporary installations. For more information on landfill gas flares selection and maintenance, visit our detailed guide.

Despite their simplicity, open flares typically achieve destruction efficiencies of 95-98% when properly designed and operated. However, they remain vulnerable to wind effects that can reduce combustion efficiency and may struggle to maintain optimal temperatures during adverse weather conditions. Most regulatory frameworks impose stricter monitoring requirements on open flares precisely because their combustion conditions cannot be as tightly controlled. Additionally, the visible flame can trigger public concern despite compliant operation, making them potentially problematic for sites with close community proximity.

“Elevated Flare Range – Ennovo Equipment” from ennovo.com.au and used with no modifications.

Enclosed Flares: Higher Efficiency with Better Control

Enclosed flares house the combustion process within a refractory-lined chamber that enables more precise temperature control and superior destruction efficiency. These systems incorporate multiple burners arranged to create optimal combustion conditions, with the enclosure maintaining consistent temperatures while minimizing the effects of ambient conditions. Temperature monitoring ports along the chamber verify proper operation while eliminating the visible flame that characterizes open systems. The controlled environment consistently achieves destruction efficiencies exceeding 99%, making enclosed flares the preferred option for regulatory compliance at larger facilities. For more on how these systems contribute to emissions reduction, explore landfill gas capture advancements.

The superior performance of enclosed flares comes with higher capital costs, greater operational complexity, and more intensive maintenance requirements. Their sophisticated control systems require more extensive operator training and specialized servicing. However, for landfills exceeding regulatory thresholds or those located near sensitive receptors, the additional investment delivers significant benefits through improved emissions control, reduced compliance risk, and minimized community impact. For more information on flare systems, check out this guide on landfill gas flares selection, installation, and maintenance.

Comparative Flare System Cost Structure

Open Flare System (2,000 SCFM): $250,000-$400,000

Enclosed Flare System (2,000 SCFM): $450,000-$750,000

Ground Flare System (2,000 SCFM): $550,000-$850,000

Note: Costs include basic equipment, controls, and installation; site-specific factors may significantly affect actual pricing

Candlestick Flares: When to Choose This Option

Candlestick flares represent a specific type of open flare designed for elevated combustion, positioning the flame well above ground level to promote better dispersion of combustion products. These systems typically feature a tall, narrow stack with the burner assembly at the top, creating the distinctive candlestick appearance. They provide effective solutions for rural locations with minimal regulatory scrutiny or for temporary gas management during system construction. Their relatively low cost and simplified maintenance make them suitable for smaller landfills generating consistent, low-volume gas flows.

The primary limitations of candlestick flares include reduced control over combustion conditions, lower destruction efficiency compared to enclosed systems, and limited ability to verify performance parameters. Most modern regulatory frameworks consider these systems adequate only for smaller operations or as backup systems to more sophisticated primary controls. When evaluating candlestick flares, operators should carefully assess whether the cost savings justify the reduced performance and potentially greater compliance challenges. For more insights on flare systems, consider reading about landfill gas flares selection, installation, and maintenance.

“Flare Systems – PRM Filtration” from www.prmfiltration.com and used with no modifications.

Ground Flares: Reducing Visual Impact

Enclosed flares are also known as ground flares. The low-profile design makes ground flares particularly valuable for sites with height restrictions, airport proximity concerns, or community aesthetic considerations. Their multi-burner configuration enables efficient turndown capability, accommodating varying gas flow rates without compromising destruction efficiency.

While ground flares typically cost more than comparable enclosed systems due to their more complex burner arrangements and larger footprint, they provide better destruction efficiencies while addressing specific operational challenges. Many designs incorporate staged burner activation to maintain optimal combustion across wide flow ranges, making them particularly valuable for landfills with highly variable gas generation rates.

For operations prioritizing community relations or facing unique site constraints, the additional investment in ground flare technology often proves worthwhile despite the higher initial cost. However, in some nations, such as the UK, it is necessary to install enclosed (ground) flares as candlestick flares are not permitted.

“Landfill gas emission reduction in …” from en.wikipedia.org and used with no modifications.

Key Components of an Effective Flare System

A comprehensive landfill gas management system extends far beyond the flare itself, encompassing collection infrastructure, conditioning equipment, control systems, and monitoring technologies. Each component plays a vital role in ensuring the overall system effectively captures, processes, and destroys landfill gas while maintaining regulatory compliance. Understanding these elements helps operators optimize both system design and ongoing performance management. For further insights, explore how landfill gas capture is advancing emissions reduction efforts.

The integrated nature of these components means that weaknesses in any single area can compromise overall system effectiveness. Successful implementation requires attention to all aspects of the gas management system, from initial collection through final destruction.

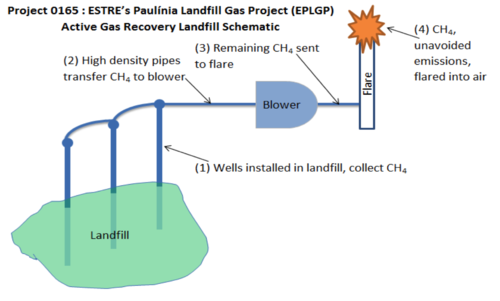

Gas Collection Network Design

The foundation of effective landfill gas management begins with a properly designed collection network that maximizes gas capture while minimizing air infiltration. This network typically consists of vertical extraction wells, horizontal collectors, and header piping systems that create negative pressure zones within the waste mass. Vertical wells, typically spaced 150-300 feet apart depending on waste characteristics and depth, extend into the waste mass to intercept gas generation zones. These wells feature perforated sections surrounded by aggregate packing that allows gas entry while filtering particulates. The well spacing, depth, and construction materials must be carefully engineered based on site-specific factors including waste composition, moisture content, and depth. For more insights, read about landfill gas capture techniques advancing emissions reduction.

Complementing the well field, header pipes connect individual wells to the central collection point, creating a branched network that gathers gas from throughout the landfill footprint. These pipes must be properly sized to accommodate projected gas flows while maintaining appropriate velocity ranges (typically 10-60 ft/sec) that prevent condensate accumulation without excessive pressure drop. Modern systems incorporate flexible connections and settlement-tolerant designs to accommodate the ongoing consolidation of waste mass that would otherwise damage rigid piping networks. The entire collection system requires careful balancing to maintain appropriate vacuum levels at each extraction point, preventing both excess air infiltration and insufficient gas capture.

Condensate Management Systems

Landfill gas emerges from the waste mass saturated with moisture that condenses as the gas cools during transport through the collection system. Effective condensate management prevents liquid accumulation that would otherwise block gas flow and damage system components. Well-designed systems incorporate strategic low points with knockouts or traps that collect condensate while allowing gas to continue flowing. These collection points must be regularly drained either through automatic systems or manual procedures to prevent backup into the gas collection network.

Beyond collection, condensate requires appropriate treatment as this liquid typically contains dissolved organics, heavy metals, and other contaminants that prohibit direct discharge. Most facilities recirculate condensate back into the waste mass or direct it to the leachate management system for treatment. Advanced facilities may incorporate dedicated condensate treatment systems using technologies such as activated carbon filtration, biological treatment, or membrane separation when condensate quality presents specific challenges.

“gas condensate partitioning …” from www.sciencedirect.com and used with no modifications.

Blower and Compression Equipment

Centrifugal blowers create the negative pressure that drives gas collection while providing the positive pressure needed to overcome system resistance and achieve proper combustion conditions at the flare. These critical components must be properly sized to deliver the required flow rates and pressure differential while accommodating the expected variations in gas generation. Most systems incorporate multiple blowers with variable frequency drives that adjust operation based on system demands, optimizing energy consumption while maintaining consistent collection efficiency.

The blower station typically includes inlet gas filtration to remove particulates that would otherwise damage equipment, along with moisture separation devices that remove entrained droplets. Sophisticated control systems monitor key parameters including suction pressure, discharge pressure, motor temperature, and gas quality to ensure safe, efficient operation. Redundancy in blower capacity represents an essential design feature, allowing continued operation during maintenance activities or equipment failures that might otherwise require system shutdown and temporary venting of untreated gas.

“Landfill Roots Blower” from www.rootsblowertech.com and used with no modifications.

Flame Arrestors and Safety Controls

Safety systems represent non-negotiable components of any landfill gas flare installation, with flame arrestors being among the most critical. These devices prevent flame propagation back through the gas line by dissipating heat through a series of small channels or mesh elements that cool potential flashback below ignition temperature. Proper installation of flame arrestors at strategic points throughout the system provides essential protection against potentially catastrophic incidents that could result from flame migration into the gas collection network or blower station.

Beyond flame arrestors, comprehensive safety controls include temperature sensors, pressure monitors, automated shutoff valves, and flame detection systems that continuously verify proper operation. These integrated safety components work together to identify potentially dangerous conditions and initiate appropriate responses ranging from simple alarms to emergency system shutdown. Modern control systems incorporate multiple layers of protection with redundant monitoring of critical parameters to ensure system safety even in the event of individual component failures.

![]()

“Flame Arrestor – an overview …” from www.sciencedirect.com and used with no modifications.

Monitoring Technology for Compliance Verification

Regulatory compliance requires comprehensive monitoring systems that document both destruction efficiency and overall system performance. Temperature sensors positioned along the flare chamber verify that minimum combustion temperatures are maintained, while flow meters record gas volumes processed. Advanced systems incorporate continuous emissions monitoring systems (CEMS) that directly measure output concentrations of regulated compounds, though most installations rely on parametric monitoring that correlates operating conditions with previously verified destruction efficiencies.

Data logging systems capture and archive this information, creating the auditable records essential for demonstrating ongoing compliance to regulatory agencies. The monitoring package typically includes gas analyzers that measure methane concentration, oxygen levels, and selected NMOCs at key points throughout the system. This information not only verifies compliance but also provides valuable operational insights that help operators optimize system performance while identifying potential maintenance needs before they develop into significant issues.

Selecting the Right Flare System for Your Landfill

The ideal flare system for any particular landfill depends on a complex interplay of regulatory requirements, site conditions, gas characteristics, and operational considerations. Making this critical decision requires thorough analysis of both current needs and anticipated future conditions throughout the landfill's active and post-closure lifecycle. The selected system must not only achieve immediate compliance but also provide the flexibility to accommodate changing conditions as waste decomposition progresses and gas generation evolves.

Site-Specific Factors That Influence Your Choice

Physical site constraints, including available space, proximity to property boundaries, and topography, significantly impact flare system selection. Limited available area may necessitate more compact enclosed designs rather than expansive open systems, while sites with close neighbors might prioritize low-profile options to minimize visual impact. Weather patterns, particularly prevailing wind directions and extreme conditions like heavy snowfall or high temperatures, should inform design choices including stack height, wind protection, and insulation requirements.

Regulatory context creates another critical consideration, with some jurisdictions imposing specific technology requirements or emissions limits that effectively mandate particular system types. Locations under stringent air quality regulation typically require enclosed flares with their superior destruction efficiency and more precise operating controls. The site's proximity to sensitive receptors—such as schools, hospitals, or residential areas—may also dictate selection of systems with enhanced emission controls beyond minimum regulatory requirements.

We recommend our ebook for all readers:

What You’ll Get in This 26-Page PDF

When you download Landfill Gas Management & Flare System Design, you’ll get a powerful, expert-written guide packed with:

✅ Clear explanations of landfill gas behavior – Understand methane generation, gas composition, and why effective management matters more than ever under global climate pledges.

✅ Flare system selection criteria – Learn the differences between open and enclosed flares, low-calorie flare technology, and how to match systems to site-specific conditions.

✅ Design, sizing, and installation best practices – Includes guidance on capacity planning, site prep, equipment requirements, and modular approaches for evolving landfill needs.

✅ Compliance made simple – Navigate EPA, ATEX, DSEAR, and Clean Air Act requirements with confidence.

✅ Maintenance & troubleshooting tips – Stay ahead of breakdowns with proven maintenance schedules and common issue fixes.

✅ Real-world insights – Case studies, lessons learned from failures, and innovative technologies shaping the future of landfill gas control.

Perfect for landfill operators, engineers, consultants, and regulators — this compact guide delivers expert insight you can use right away to improve performance, cut emissions, and stay compliant.

Gas Volume and Quality Considerations

Gas generation projections drive fundamental system sizing decisions, with projected peak flow rates determining the required capacity and expected minimum flows influencing turndown capabilities. These projections should incorporate comprehensive modeling of waste composition, filling rates, and decomposition kinetics to develop accurate expectations for both near-term and long-term gas production. Most installations benefit from modular designs that can accommodate expansion or contraction as actual gas generation inevitably varies from initial projections.

Gas quality parameters, including methane content, oxygen levels, and NMOC concentrations, significantly impact both system selection and specific design details. Lower methane concentrations may require auxiliary fuel systems to maintain stable combustion, while elevated hydrogen sulfide levels necessitate special materials selection to prevent corrosion. Thorough gas testing during system design provides essential information for proper equipment selection, with ongoing monitoring informing operational adjustments as gas composition evolves throughout the site's lifecycle.

Budget Constraints vs. Regulatory Requirements

Financial considerations inevitably influence technology selection, with significant cost differentials between basic open flares and sophisticated enclosed systems. However, focusing exclusively on initial capital costs often proves shortsighted given the long operational life of these systems and the potentially severe consequences of non-compliance. Life-cycle cost analysis should incorporate not only purchase and installation expenses but also projected operational costs, maintenance requirements, and potential regulatory penalties associated with different system options.

Finding the optimal balance between budgetary constraints and performance requirements represents a key challenge in system selection. Many facilities achieve this balance through phased implementation approaches that install basic systems initially with provisions for future upgrades as gas volumes increase or regulatory requirements evolve. This approach minimizes upfront capital expenditure while maintaining pathways to enhanced performance when conditions warrant more sophisticated controls.

“enclosed flare (Irish EPA 2012 …” from www.researchgate.net and used with no modifications.

Installation Best Practices for Maximum Effectiveness

Proper installation lays the foundation for long-term system performance and regulatory compliance. Even the most sophisticated flare technology will underperform if installation fails to follow industry best practices or cuts corners to reduce initial costs. Successful projects combine thoughtful planning, quality materials, experienced contractors, and thorough commissioning to ensure systems operate as designed from initial startup through their expected service life.

Proper Sizing and Capacity Planning

Accurate capacity planning requires thorough modeling of expected gas generation rates throughout the landfill's active period and post-closure care timeline. Projections should incorporate waste acceptance rates, composition analysis, and decomposition kinetics to develop reasonable expectations for both peak and minimum flows. Most installations benefit from incorporating a safety factor of 15-25% above projected maximum rates to accommodate unexpected variations while ensuring consistent regulatory compliance. For more information on selecting and maintaining these systems, explore our guide on landfill gas flares.

Turndown capability—the system's ability to operate efficiently across varying flow rates—represents another critical sizing consideration. Gas generation typically increases during a landfill's active period before gradually declining during post-closure, requiring systems that maintain efficient operation across this evolution. Modern installations often incorporate multiple flares or staged combustion systems that enable selective operation of only those components needed to handle current flow rates, maintaining optimal combustion conditions despite significant variations in gas production.

Location Factors for Optimal Performance

Flare system placement requires careful consideration of multiple factors including wind patterns, proximity to operations areas, accessibility for maintenance, and setback requirements from structures and property boundaries. Regulatory standards typically specify minimum separation distances based on thermal radiation analysis, ensuring safe conditions in surrounding areas. The system location must also provide sufficient access for maintenance activities including conduit cleanout, blower service, and periodic component replacement. For more information on safety measures, explore landfill gas monitoring techniques.

Utility requirements represent another location consideration, with most systems requiring reliable electrical service for blowers, controls, and monitoring equipment. Backup power provisions become essential for continuous compliance, particularly at sites where gas buildup during extended outages could create safety hazards or significant emissions events. The system foundation must accommodate equipment weight while providing appropriate elevation to prevent water intrusion during severe weather, with proper drainage features directing precipitation away from critical components.

Construction Timeline and Process Overview

Installation timelines for landfill gas flare systems typically range from 3-6 months depending on system complexity, site conditions, and equipment lead times. The process begins with site preparation including foundation construction, utility installation, and access road development. Equipment delivery schedules should be carefully coordinated to minimize on-site storage requirements while ensuring all components arrive in appropriate sequence for efficient installation.

Commissioning represents the critical final phase, thoroughly testing all system components under actual operating conditions before transitioning to routine operation. This process typically includes pressure testing of gas lines, calibration of all monitoring devices, verification of control system functions, and performance testing to confirm destruction efficiency meets design specifications. Comprehensive documentation created during commissioning establishes the baseline for future performance evaluation while providing essential records for regulatory compliance verification.

Operational Challenges and Solutions

Even perfectly designed and installed flare systems face operational challenges throughout their service lives. Understanding these common issues and implementing appropriate solutions helps maintain consistent performance while minimizing compliance risks and operational disruptions. Proactive management strategies that anticipate potential problems almost always prove more effective than reactive approaches that address issues only after they impact system performance.

Dealing with Fluctuating Gas Quality

Gas composition inevitably varies throughout a landfill's lifecycle, with methane content typically increasing during active filling before gradually declining during post-closure. These variations can significantly impact combustion stability, potentially causing flame instability or even extinction when methane concentrations fall below minimum thresholds (typically around 20% by volume). Modern control systems address this challenge through continuous monitoring coupled with automated adjustments to air-fuel ratios, maintaining stable combustion despite changing gas quality.

For sites experiencing particularly challenging gas quality issues, supplemental fuel systems can provide additional combustion support during periods of low methane content. These systems, typically using propane or natural gas, automatically activate when methane concentrations drop below specified thresholds, ensuring continuous destruction of landfill gas components even when methane alone cannot sustain stable combustion. While adding operational complexity and cost, these backup systems often prove essential for maintaining compliance at sites with marginal gas quality or during transition periods as landfills move from active to post-closure status.

“Low Calorie Range” from www.landfillsystems.co.uk and used with no modifications.

Weather Impact on System Performance

Environmental conditions significantly influence flare system performance, with wind, precipitation, and temperature extremes all presenting potential challenges. High winds can disrupt flame patterns in open flares, potentially reducing destruction efficiency or even extinguishing the flame under severe conditions. Enclosed flares provide superior protection against these effects, though even these systems require proper design features including wind shields and appropriate stack height to maintain optimal performance during adverse conditions.

Temperature extremes create different challenges, with cold weather potentially causing condensate freezing that blocks gas flow while extreme heat can affect electronic control systems. Effective designs incorporate appropriate insulation, heat tracing for vulnerable components, and climate-controlled enclosures for sensitive electronics. Precipitation management requires proper grading around equipment, covered areas for maintenance activities, and drainage systems that prevent water accumulation near critical components.

Troubleshooting Common Flare Problems

Effective troubleshooting begins with identifying patterns that distinguish between normal operational variations and actual system problems requiring intervention. Monitoring trends in key parameters—including combustion temperature, methane concentration, and pressure differentials—often reveals developing issues before they trigger compliance concerns. Most operational problems fall into categories including combustion instability, control system malfunctions, blower issues, or collection system blockages, each requiring specific diagnostic approaches and resolution strategies.

Comprehensive troubleshooting procedures should be documented in the system's operation and maintenance manual, providing operators with clear guidance for addressing common issues. These procedures typically include decision trees that systematically evaluate potential causes based on observed symptoms, helping even less experienced personnel identify and resolve problems efficiently. Regular training ensures operations staff recognize developing issues early and implement appropriate responses before minor concerns develop into significant problems affecting system performance or compliance status.

Maintenance Requirements to Ensure Continuous Compliance

Preventive maintenance provides the foundation for reliable flare system operation, identifying and addressing potential issues before they impact performance or compliance. A structured maintenance program incorporates daily observations, weekly inspections, monthly preventive services, and annual comprehensive evaluations to ensure all components function as designed throughout their expected service lives. This proactive approach minimizes unplanned downtime while extending equipment life and reducing overall operational costs. For more information, check out our guide on landfill gas flares selection, installation, and maintenance.

Daily, Weekly and Monthly Maintenance Tasks

Daily operational checks focus on confirming basic system functionality through quick observations of key parameters including combustion temperature, blower operation, and flame condition. These brief inspections, typically requiring less than 30 minutes, provide early warning of developing issues while creating the documented record of system oversight often required by regulatory permits. Weekly maintenance expands this oversight to include more detailed examination of components including condensate management systems, control panel indicators, and valve positions.

Monthly preventive maintenance involves more comprehensive activities including blower belt inspection, lubrication of moving components, calibration verification for monitoring instruments, and cleaning of critical elements. These activities typically require system shutdown, making advance planning essential to minimize compliance impact. Well-structured maintenance programs schedule these activities during periods of lower gas generation when possible, maintaining environmental protection while ensuring all components receive appropriate preventive care.

Maintenance Frequency by Component

Blower System: Weekly inspection, monthly belt check, quarterly lubrication

Flame Arrestors: Monthly inspection, quarterly cleaning

Thermocouples: Monthly verification, annual calibration

Control Systems: Weekly function check, monthly backup test

Condensate Management: Daily observation, weekly drainage check

Note: Actual requirements may vary based on equipment manufacturer recommendations and site-specific conditions

Equipment Inspection Schedules

Comprehensive equipment inspections conducted on quarterly and annual schedules provide deeper evaluation of system condition beyond routine maintenance activities. These inspections typically include vibration analysis of rotating equipment, thermographic scanning of electrical components, and detailed examination of refractory materials in enclosed flares. The resulting condition assessments inform maintenance planning and capital budgeting by identifying components approaching end-of-life before actual failure occurs.

Many facilities supplement internal inspection programs with manufacturer service agreements that provide specialized expertise for complex components. These agreements typically include annual visits from factory-trained technicians who perform detailed evaluations, make necessary adjustments, and update control software to current versions. While representing an additional operational cost, these professional services often identify developing issues that might be missed by on-site personnel, particularly for sophisticated electronic controls or specialized combustion components.

Parts Replacement and Lifecycle Considerations

Proactive replacement of wear components before failure occurs represents a cornerstone of effective maintenance programs. Critical components including thermocouples, ignition systems, blower belts, and flame sensors have predictable service lives influenced by operating conditions and usage patterns. Tracking the age and condition of these elements enables scheduled replacement during planned maintenance periods rather than emergency repairs following unexpected failures that might create compliance issues.

Comprehensive spare parts inventory management ensures critical components remain available when needed while minimizing capital tied up in excess inventory. Most facilities maintain on-site stocks of frequently needed items including thermocouples, ignitors, filters, and belts while establishing reliable supply chains for less common components. The spare parts strategy should balance the cost of inventory against the potential compliance and operational impacts of extended downtime waiting for replacement components, with critical path analysis identifying those elements deserving priority in inventory management.

Advanced Technologies Enhancing Flare System Performance

Technological advancements continue transforming landfill gas management, with innovations improving both performance and operational efficiency. Modern flare systems incorporate sophisticated controls, advanced monitoring capabilities, and integrated data management that enable unprecedented levels of optimization and compliance assurance. Understanding these emerging technologies helps landfill operators evaluate potential upgrades that might enhance their existing systems while preparing for future regulatory requirements.

While established flare technologies have proven effective for decades, ongoing innovation addresses persistent challenges including emissions verification, operational efficiency, and remote monitoring capabilities. These advancements typically focus on enhancing control precision, improving data collection, and enabling more sophisticated analysis of system performance across varying operating conditions.

The integration of these technologies creates intelligent systems capable of not only maintaining regulatory compliance but also optimizing performance to reduce operational costs and environmental impact. As regulatory requirements continue evolving toward more stringent emissions standards, these advanced capabilities increasingly represent not just operational enhancements but essential tools for maintaining compliance in a changing regulatory landscape. For more insights on optimizing flare systems, explore proven ways to optimize your flare systems.

Automated Control Systems

Modern automated control systems represent a significant advancement beyond the basic temperature and flow monitoring of earlier generations. These sophisticated platforms continuously monitor multiple parameters including methane concentration, oxygen levels, combustion temperature, and flow rates, making real-time adjustments to maintain optimal conditions despite changing gas characteristics. Proportional-integral-derivative (PID) control algorithms enable precise management of critical parameters, maintaining tight operational tolerances that maximize destruction efficiency while minimizing auxiliary fuel consumption.

Advanced burner management systems provide another layer of automation, controlling startup sequences, flame verification, and shutdown procedures to ensure safe operation under all conditions. These systems incorporate multiple safety interlocks that prevent operation under potentially dangerous conditions while automatically documenting all operational parameters for compliance verification. Self-diagnostic capabilities continuously monitor critical components, alerting operators to developing issues before they impact system performance or safety.

The integration of programmable logic controllers (PLCs) with human-machine interfaces (HMIs) creates intuitive operational platforms that simplify system management while providing detailed performance data. These systems enable operators to easily adjust setpoints, monitor trends, and troubleshoot issues through user-friendly interfaces that reduce training requirements while improving operational consistency. The resulting automation not only enhances performance but also reduces labor requirements, allowing facilities to maintain compliance with fewer dedicated personnel.

Remote Monitoring Capabilities

Cloud-based monitoring platforms have revolutionized flare system oversight by enabling real-time performance verification from any internet-connected device. These systems transmit operational data to secure servers where it becomes accessible to authorized personnel through web portals or mobile applications. The resulting visibility allows managers to verify compliance status without physical site visits while enabling technical specialists to troubleshoot issues remotely, reducing response times and minimizing system downtime.

Data Analytics for Performance Optimization

Advanced analytics applications transform operational data from simple compliance documentation into valuable insights that drive performance optimization. These tools apply statistical analysis and machine learning techniques to identify patterns and correlations that might not be apparent through conventional monitoring approaches. The resulting insights help operators optimize air-fuel ratios, identify developing maintenance issues before they cause failures, and understand the complex interactions between operational parameters that influence overall system performance.

Real-World Success: Case Studies in Landfill Gas Management

Examining successful landfill gas management implementations provides valuable insights into practical applications of flare system technologies across diverse operating environments. These real-world examples demonstrate how facilities have addressed specific challenges through thoughtful system selection, innovative implementation approaches, and effective operational strategies. The lessons drawn from these experiences help other operators identify solutions to their own challenges while avoiding potential pitfalls encountered by earlier adopters.

Each case study represents a unique combination of site conditions, regulatory requirements, and operational priorities that influenced technology selection and implementation approach. Despite these differences, common themes emerge regarding the importance of proper sizing, attention to maintenance requirements, and the value of integrated monitoring systems in ensuring long-term compliance and operational efficiency.

These examples also highlight the evolution of landfill gas management practices over time, with many facilities progressively upgrading their systems to incorporate new technologies as they become available and proven in field applications. This incremental approach allows operators to balance capital investment constraints against performance requirements while maintaining continuous compliance throughout the upgrade process. For more information on how to effectively manage these upgrades, consider exploring landfill gas flares selection and maintenance.

Implementation Outcomes by Site Category

Small Rural Landfill (50-200 TPD): Basic open flare with manual controls, 95% destruction efficiency, $150-300K implementation cost

Mid-Size Suburban Landfill (200-500 TPD): Enclosed flare with automated controls, 98% destruction efficiency, $500-800K implementation cost

Large Urban Landfill (500+ TPD): Multiple enclosed flares with advanced controls, 99% destruction efficiency, $1-3M implementation cost

Note: Actual costs and performance metrics vary significantly based on site-specific factors and regional conditions

Small Landfill Achieves Compliance with Basic Flare

The Cedar County Landfill faced a common challenge when gas testing revealed methane emissions exceeding regulatory thresholds despite their relatively small waste volume (approximately 75 tons per day). With limited financial resources and projected gas flows of only 150-250 standard cubic feet per minute (SCFM), they needed an economical solution that would achieve compliance without excessive capital investment or operational complexity. After evaluating options, they implemented a basic open flare system with simplified controls, strategically sized to accommodate their projected gas generation curve while minimizing initial investment.

The implementation successfully achieved regulatory compliance with capital costs under $200,000 and annual operating expenses below $30,000. Key success factors included careful attention to collection system design—installing vertical wells at appropriate spacing despite the temptation to reduce costs through wider spacing—and implementation of a structured maintenance program despite limited staff resources. The resulting system has maintained consistent compliance for over five years while requiring less than 10 hours of weekly operator attention, demonstrating that even basic systems can provide effective gas management when properly designed and maintained.

“methane problem …” from www.cascadepbs.org and used with no modifications.

Large Operation's Transition to Advanced Enclosed System

Riverside Regional Landfill's experience illustrates the evolution from basic to advanced gas management as regulations and operational requirements changed over time. This 500-acre facility initially installed a basic open flare system during early operations when gas volumes were minimal and regulatory requirements less stringent. As waste volumes increased and nearby residential development created greater community scrutiny, they transitioned to an enclosed flare system with improved destruction efficiency and reduced visible emissions. Their most recent upgrade incorporated multiple enclosed flares with advanced controls enabling efficient operation across widely varying flow rates while providing the redundancy essential for continuous compliance.

This phased implementation approach allowed the facility to distribute capital costs over multiple budget cycles while maintaining continuous compliance throughout the transition periods. Each system upgrade incorporated lessons from previous operations, with particular attention to addressing maintenance challenges encountered with earlier equipment. The current system features comprehensive remote monitoring capabilities that enable management verification of compliance status without physical site visits, reducing staff requirements while improving oversight. Their experience demonstrates the value of designing initial systems with provisions for future expansion and upgrade as conditions evolve throughout the site's operational life. For more information on optimizing flare systems, consider exploring ways to optimize your flare systems.

Beyond Flaring: Alternative Approaches to Landfill Gas

While flaring remains the most common approach to landfill gas management, beneficial use alternatives offer opportunities to transform this potential liability into a valuable resource. These technologies capture the energy content of landfill gas, converting it into useful forms including electricity, pipeline-quality natural gas, or direct thermal applications. When economically viable, these approaches provide both environmental benefits through greenhouse gas reduction and financial returns that can offset gas management costs.

- Electricity Generation: Using internal combustion engines, turbines, or microturbines to produce power for on-site use or grid sale

- Medium-BTU Direct Use: Minimally processed gas used directly in boilers, kilns, or other thermal applications

- Renewable Natural Gas: Highly purified biomethane meeting pipeline quality standards

- Alternative Fuels: Compressed or liquefied gas used for vehicle fueling or industrial applications

Determining whether beneficial use makes sense for a particular facility requires careful analysis of multiple factors including gas quantity, quality, and consistency; available infrastructure; local energy markets; and potential incentives such as renewable energy credits or carbon offset values. Most successful projects require minimum gas flows exceeding 300-500 SCFM with methane content above 45% to provide sufficient energy content for economical recovery. Projects must also consider long-term gas generation projections, as most energy recovery systems require 10-15 years of operation to achieve positive financial returns on the substantial capital investment required.

Even when implementing beneficial use projects, flare systems remain essential components of the overall gas management strategy. These systems provide backup capacity during maintenance periods, handle excess gas during peak generation periods, and ensure continuous compliance capability if energy recovery becomes temporarily uneconomical due to market conditions or equipment issues. Most regulatory frameworks require functional flare systems regardless of beneficial use implementation, recognizing their critical role in ensuring continuous emissions control under all operational scenarios.

The decision to pursue beneficial use typically emerges from a comprehensive feasibility study examining technical, economic, and regulatory factors specific to each site. These studies evaluate projected gas quantity and quality throughout the project lifecycle, assess available technologies against site characteristics, and develop detailed financial models incorporating capital costs, operating expenses, and projected revenue streams. Only through this rigorous analysis can operators determine whether beneficial use represents a viable alternative to simple flaring for their particular circumstances.

Energy Recovery Potential

Landfill gas typically contains 450-550 BTU per standard cubic foot, representing approximately half the energy content of natural gas but still offering substantial recovery potential at sites with significant gas generation. A mid-sized landfill producing 1,000 SCFM of landfill gas could potentially generate 1.5-2 megawatts of electricity—enough to power approximately 1,500-2,000 homes—through properly designed energy recovery systems. This energy value, previously wasted through simple flaring, can create significant revenue streams while providing renewable energy benefits that extend beyond simple regulatory compliance.

When to Consider Beneficial Use Projects

Beneficial use projects become most attractive when specific conditions align to create favorable economics and operational feasibility. Key indicators supporting potential beneficial use include gas flows exceeding 500 SCFM with projected stability for 10+ years; methane content consistently above 45%; favorable energy prices or renewable energy incentives in the local market; and available infrastructure for energy transmission or utilization. Sites located near industrial facilities with consistent thermal energy requirements often present particularly favorable conditions for direct-use applications that avoid the efficiency losses associated with electricity generation.

The regulatory context significantly influences beneficial use viability, with programs including Renewable Portfolio Standards, carbon offset protocols, and specific landfill gas incentives potentially improving project economics beyond basic energy values. These non-energy benefits can transform marginally feasible projects into attractive investments, particularly when stacked with operational savings from reduced flare system maintenance and potential reduction in carbon liabilities. A comprehensive evaluation should examine all potential value streams, recognizing that regulatory changes and energy market evolution may significantly impact long-term project viability throughout the recovery system's operational life.

Taking Action: Steps to Improve Your Landfill's Environmental Profile

Improving landfill gas management represents one of the most effective steps operators can take to enhance their environmental profile while ensuring regulatory compliance. Beginning with a comprehensive assessment of current conditions—including gas testing to characterize both quantity and composition—operators can develop strategic improvement plans tailored to their specific circumstances. These plans should incorporate both near-term actions addressing immediate compliance concerns and long-term strategies accounting for evolving regulatory requirements and gas generation patterns throughout the site's lifecycle. Working with experienced consultants, equipment suppliers with proven field experience, and regulatory authorities throughout the planning process helps ensure the resulting system achieves both operational and compliance objectives while remaining economically sustainable for the facility's particular circumstances.

Frequently Asked Questions

The following questions address common concerns regarding landfill gas flare systems, providing practical guidance based on industry experience and regulatory requirements. While specific answers may vary depending on regional regulations and site-specific factors, these general responses offer starting points for understanding key considerations in flare system selection, implementation, and operation.

How much does a typical landfill flare system cost?

Flare system costs vary significantly based on type, capacity, and site-specific requirements, with typical ranges from $150,000 for basic open flares at small sites to several million dollars for sophisticated enclosed systems at large facilities. For planning purposes, operators can estimate approximately $100-150 per SCFM of capacity for open flare systems and $200-300 per SCFM for enclosed systems, though these figures exclude site preparation, gas collection infrastructure, and auxiliary components that may significantly impact total project costs. A comprehensive implementation budget should include not only equipment purchase but also site preparation, installation labor, permitting fees, initial testing, and commissioning expenses that collectively may represent 50-100% above basic equipment costs.

What destruction efficiency can I expect from different flare types?

Destruction efficiency varies primarily by flare type, with properly designed and operated open flares typically achieving 95-98% destruction of methane and NMOCs under favorable conditions. Enclosed flares provide superior performance with documented destruction efficiencies of 98-99.9% when operating within design parameters, making them the preferred option for sites requiring maximum emissions control. Ground flares offer similar destruction efficiency to enclosed systems, typically achieving 98-99.5% destruction while providing reduced visual impact compared to tall stack designs. For more information on flare selection, check out this guide on landfill gas flares.

Actual performance depends heavily on proper sizing, appropriate controls, and consistent maintenance regardless of flare type. Systems operating outside their designed flow range—either with excessive or insufficient gas supply—typically experience reduced destruction efficiency that may fall below regulatory requirements. Similarly, improper air-fuel ratios, inadequate temperature monitoring, or failure to maintain critical components can compromise performance of even the most sophisticated systems if not properly addressed through comprehensive operational and maintenance programs.

Most regulatory frameworks specify minimum destruction efficiency requirements, typically 98% for NMOC compounds, that effectively mandate enclosed flare technology for larger facilities or those located in sensitive areas. Performance verification through stack testing provides the definitive measure of actual destruction efficiency, with most permits requiring initial testing followed by periodic confirmation testing throughout the system's operational life. For more information on flare technology, you can explore the detailed guide on landfill gas flares.

How long does a flare system typically last before replacement?

- Flare Structure/Stack: 15-25 years with proper maintenance and corrosion protection

- Refractory Lining (enclosed flares): 5-10 years depending on operating temperatures and cycles

- Burner Assemblies: 7-12 years with regular maintenance and cleaning

- Control Systems: 10-15 years, though electronic components may require earlier upgrade

While these components represent the core flare system, auxiliary equipment including blowers, knockout pots, and flame arrestors typically require replacement or major overhaul on shorter cycles, often 5-7 years depending on operating conditions and maintenance practices. Monitoring instruments, particularly those exposed to landfill gas constituents, may require even more frequent replacement, with thermocouples and gas analyzers typically lasting 2-4 years before calibration becomes unreliable.

A well-structured capital replacement program anticipates these varying lifecycle timelines, budgeting for progressive component replacement rather than complete system overhaul. This approach distributes capital requirements more evenly while allowing incorporation of technological improvements as they become available. Most facilities develop 5-10 year capital plans specifically addressing flare system components, scheduling replacements based on both age and condition assessment to optimize expenditures while maintaining reliable operation.

System longevity correlates strongly with maintenance practices, with well-maintained systems consistently achieving the upper ranges of expected component life. Conversely, neglected systems often require premature replacement, particularly of critical components subjected to corrosive gas constituents or excessive thermal cycling. The quality of initial equipment selection also significantly impacts longevity, with industrial-grade components designed specifically for landfill applications typically delivering substantially longer service life than general-purpose alternatives despite higher initial costs.

Can landfill flare systems operate in all weather conditions?

Properly designed flare systems can maintain effective operation across a wide range of weather conditions, though extreme environments require specific design considerations to ensure reliability. Cold weather installations need heat tracing for condensate lines, insulated enclosures for sensitive components, and sometimes supplemental gas heating to prevent condensate freezing that could restrict flow. Hot weather operation requires attention to cooling systems for electronic components, with sun shades, ventilation, or air conditioning for control enclosures preventing temperature-related failures during extreme heat events. All installations should consider local precipitation patterns, incorporating appropriate drainage, elevated equipment mounting, and weather protection for maintenance access points to ensure continuous operation regardless of rainfall or snowfall conditions.

What permits are required for installing a landfill gas flare?

Permit requirements vary by jurisdiction but typically include air quality permits addressing emissions from the combustion process, with requirements scaling based on system size and potential emissions levels. Major metropolitan areas with severe air quality challenges often impose particularly stringent requirements, sometimes requiring lowest achievable emission rate (LAER) technology regardless of cost implications. Some jurisdictions also require construction permits addressing foundation design, electrical connections, and fire safety provisions before installation can proceed.

The permitting process typically begins with preliminary regulatory consultation to identify specific requirements applicable to the proposed installation. Most jurisdictions require detailed emissions calculations based on expected gas composition and flow rates, along with dispersion modeling demonstrating compliance with ambient air quality standards. System design documentation must demonstrate that the selected technology can achieve required destruction efficiency under the expected range of operating conditions, often requiring vendor guarantees or reference to performance data from similar installations.

Larger installations may trigger New Source Review (NSR) or Prevention of Significant Deterioration (PSD) requirements under federal regulations, substantially increasing both application complexity and processing time. These major source permits typically require formal public comment periods, detailed best available control technology (BACT) analysis, and sometimes ambient air monitoring before approval. Working with experienced consultants familiar with local regulatory requirements helps navigate these complex processes while minimizing delays that could impact compliance deadlines or operational schedules.

Once operational, most permits require ongoing monitoring and regular reporting to demonstrate continuous compliance with emissions limitations and operating parameters. These requirements may include continuous parameter monitoring, periodic source testing, and detailed recordkeeping documenting system operation and maintenance activities. Understanding these ongoing obligations during the initial permitting process helps ensure the selected system includes appropriate monitoring capabilities while operational budgets incorporate necessary compliance activities throughout the system's operational life.

Flare systems are an essential component in the management of landfill gas. They play a crucial role in reducing methane emissions, which are a significant environmental concern. By efficiently combusting the gas, flare systems help in mitigating the greenhouse effect. For those interested in the technical aspects of these systems, understanding the selection, installation, and maintenance of landfill gas flares is vital to ensuring optimal performance and compliance with environmental regulations.

US Landfill Gas Resources: A Booming Green Energy Sector

Untapped U.S. Landfill Gas Resources are an Opportunity for Green Investment The American landfill gas (LFG) sector has seen a big change in recent years. It's now a key player in the country's biogas world. Even though it's only 23% of over 2,500 biogas systems now installed nationwide, it captures 72% of all biogas by […]

Landfill Gas Management Solutions

You know the tough part about landfill gas is that the problems rarely show up one at a time. Odors, off-site migration concerns, wellfield instability, and methane emissions can all trace back to the same root issue: gas is finding an easier path than the one you built for it. All this leads to the […]

What is Landfill Gas: Composition Uses and Benefits

Landfill gas (LFG) is a natural, clean-burning byproduct created when bacteria decompose organic waste (food, paper, wood) in landfills. It consists primarily of roughly 50% methane (CH4) and 50% carbon dioxide (CO2), along with trace amounts of nitrogen, oxygen, and volatile organic compounds. LFG is a potent greenhouse gas but is increasingly captured and used […]

Gas Flare Systems: Enhancing Safety and Efficiency in Landfill Gas Operations

Proper landfill gas flare systems can achieve up to 99.5% methane destruction efficiency, reducing environmental impacts. Enclosed systems enhance emission control. Safety features like flame arrestors prevent incidents. Flares integrate with energy recovery, transforming waste gases into renewable resources, offering compliance and sustainability benefits for landfill operations…