In this article, we discuss landfill gas extraction systems and how the landfill gas collected is used to create renewable energy. Waste heat is used in a combined heat & power (CHP) system to improve overall efficiency.

Landfill gas (LFG) is extracted from the landfill by exerting a small negative suction pressure on boreholes driven into the waste after landfilling, or through wells built up progressively while the waste is being deposited. This method supports an effective landfill gas management plan.

Key Takeaways

- Gas composition: Landfill gas contains 50-70% methane and 25-50% carbon dioxide, making it a valuable renewable energy source extracted through negative suction pressure systems

- Core equipment: Systems use blowers to create suction, generators with internal combustion engines for electricity production, and knock-out pots to manage condensation in pipework

- Energy efficiency: Combined Heat and Power (CHP) systems capture up to 40% additional energy as waste heat for district heating or direct industrial use

- Environmental benefits: Flaring excess gas converts methane to carbon dioxide, reducing greenhouse gas impact while maintaining safe methane levels below 500 ppm

- Production lifespan: Sites generate usable gas for 5-15 years with systems designed to accommodate landfill expansion and changing gas production rates

- Multiple applications: Collected gas can generate electricity for the grid, replace natural gas in nearby factories, or provide heating through district heating schemes

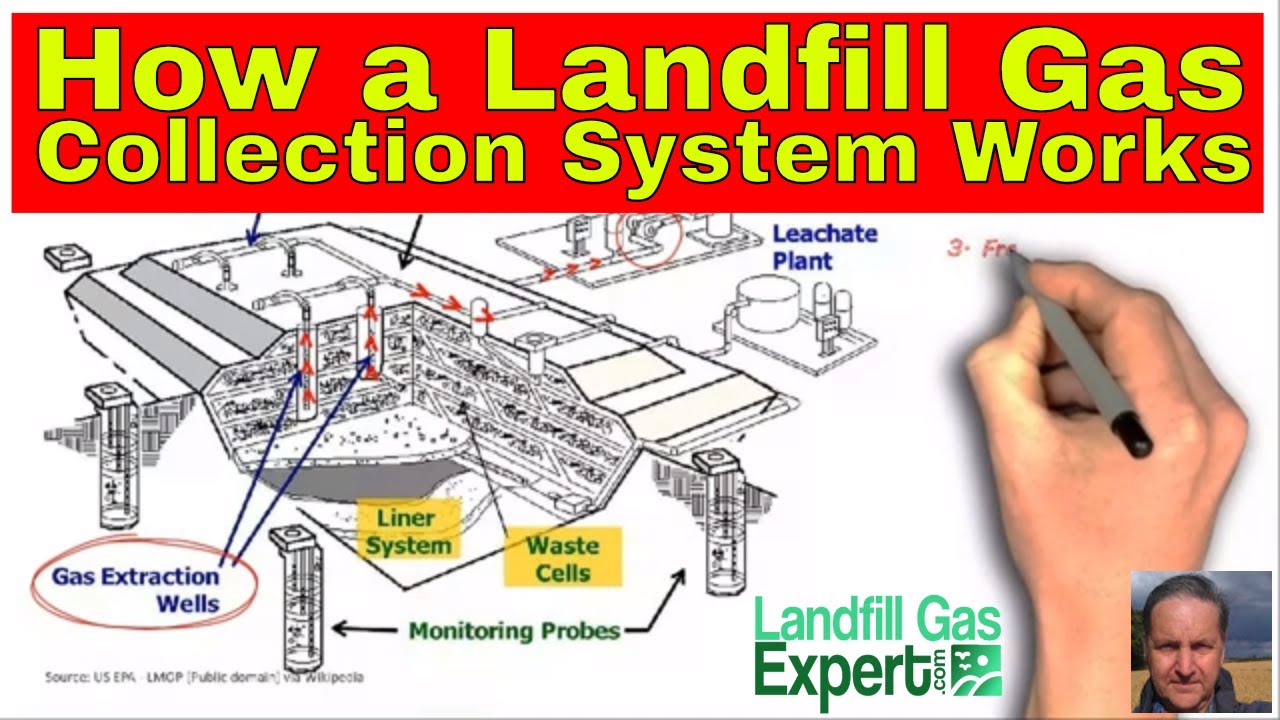

Landfill Gas Extraction Pipework

A network of landfill gas extraction pipework is installed within the landfill cap. All pipes lead to a “manifold” that connects to the landfill gas compound.

Engineers must take care to avoid low points where water can accumulate in the pipework and block airflow under low suction pressures. At appropriate intervals, so-called “knock-out pots” are installed.

These devices drain condensation through a pre-primed water trap while maintaining the necessary suction pressure.

Gas Composition and Collection Methods

Landfill gas is mostly made up of methane and carbon dioxide. Methane typically makes up between 50% and 70% of the gas, while carbon dioxide forms about 25% to 50%.

Gas collection usually starts once a section of the landfill, known as a cell, is closed to further waste. Systems use vertical wells or horizontal trenches, and many facilities include flaring systems to burn off extra gas during periods when equipment is inactive.

The Blower as Used in Landfill Gas Extraction Systems

A blower creates suction by drawing gas into the power generation plant while establishing pressure at the inlet. The blower, located in the Landfill Gas Compound, is adjusted to deliver gas to the generator, a flare system, or both.

Only landfill gas with sufficient methane for effective combustion enters the generator.

Vacuum systems are applied to create low pressure in the collection wells, which draws the gas through perforated piping. Multistage centrifugal blowers can serve many vent pipes at once and help to maintain even suction throughout the system.

The Generator as Used in Landfill Gas Extraction Systems

The generator commonly uses an internal combustion engine similar to a diesel engine. The first landfill gas-generating sets were modified Caterpillar Diesel sets with coupled dynamo units. Turbines may also burn the gas to generate electricity.

One early installation in the 1980s used an old English Electric jet-fighter turbine.

Electric power produced feeds into the local grid using advanced equipment. This system synchronises the alternating current to match the grid's phase and frequency.

Generator selection is based on the quality and volume of the collected methane. Matching the generator to the gas output helps to keep performance steady and safe.

Other uses of Landfill Gas

When a high-consumption gas user is near the landfill, piping the gas directly to a factory becomes cost-effective. The gas replaces natural gas with a sustainable, lower-cost alternative. This method follows proper landfill gas management practices and supports the methane pledge.

In many European countries, waste heat from power generation fuels CHP schemes, also known as “district heating”. The low-grade heat from the generator's cooling jacket is used to heat homes and factories.

Lagged and heat-insulated pipes are installed in towns or districts. Unwanted hot water from the waste-to-energy plant is pumped into these systems. The water flows through radiators to warm homes and factories.

Flaring operations serve as a safety and environmental control measure. Burning off the excess gas converts methane to carbon dioxide, which helps to reduce greenhouse gas impacts.

“Basic Information about Landfill Gas …” from www.epa.gov and used with no modifications.

Implementing District Heating

Landfill gas-generating engines produce up to 40% of their energy output as water-cooled heat. It is wasteful both in terms of the environment and economically not to use this heat. Use is relatively simple when used to heat a hot-water piped district heating system.

District heating schemes were rare in the UK until 2008. The Byker District Heating Scheme in Newcastle-upon-Tyne and a scheme in Sheffield were well publicised. Neither of those utilised landfill gas as the heat source.

Since 2008, some CHP schemes have emerged in the UK. Most are related to Anaerobic Digestion Plant CHP.

There is no central record of landfill gas EfW installations in the UK.

Other Equipment Used in Landfill Gas Extraction Systems

Equipment is provided for burning excess gas via flares. Such devices operate during periods when atmospheric changes lower methane levels, making the gas unsuitable for flaring.

Many sites install systems to remove water from the gas before combustion. This step reduces water saturation and improves system performance.

Every landfill gas generation system faces a high corrosion potential due to warm gas, oxygen, and corrosive impurities. The industry has enhanced corrosion resistance so that modern plants rarely experience downtime.

Enhanced Extraction Well Techniques and Compliance Standards

Vertical extraction wells are widely used to collect landfill gas. Engineers drill these wells into the waste and connect them with laterals that channel the gas.

Many sites now employ advanced well systems that enclose perforated pipes within large-diameter caissons, often ranging from 24 to 36 inches.

Horizontal collection systems, laid in trenches, are used in deeper or actively filled areas and are sometimes combined with vertical wells to form an integrated network.

Regulatory standards require that systems maintain methane concentrations below 500 ppm above background levels, ensuring safe operation.

For How Long Do Sites Yield Useful LFG?

Certain landfill sites yield usable gas for no more than five years. Others generate for almost 15 years and show little decrease in gas flow.

Engineers plan these systems to cope with changes in gas production. Provisions for landfill expansion and future gas management are built into the design to keep operations stable.

Disclosure: The details in this article are based on verified industry research, technical guidelines, and documented case studies. The research process followed standard landfill gas management practices, and reference methods are consistent with established industry standards.

Frequently Asked Questions (FAQs)

How does landfill gas extraction work?

Landfill gas extraction uses negative suction pressure applied through boreholes or wells driven into waste deposits. A network of pipework connects to a central manifold that channels gas to generators, flare systems, or direct users. Blowers create the necessary vacuum to draw gas through perforated pipes.

What equipment is needed for a landfill gas extraction system?

Key equipment includes:

- Vertical or horizontal extraction wells with perforated piping

- Valves that are used to control the negative extraction pressure evenly

- Blowers (often multistage centrifugal) to create suction

- Generators with internal combustion engines or turbines

- Flare systems for excess gas burning

- Knock-out pots for condensation drainage

- Water removal systems to improve combustion efficiency

How long do landfill gas systems remain productive?

Landfill sites typically yield usable gas for 5-15 years from the same waste. If landfilling continues, the most productive extraction cells will vary, but the site itself will continue to yield gas. That way, some sites show a minimal decrease in gas flow over extended periods. The duration depends on waste composition, landfill size, and management practices.

What are the main uses for collected landfill gas?

- Electricity generation through generators that feed power into the local grid

- Direct industrial use by piping gas to nearby factories as a natural gas replacement

- District heating using waste heat from generators to heat homes and buildings

- Flaring for safety and environmental control when gas cannot be used productively

How efficient are landfill gas energy systems?

Generators can produce electricity while simultaneously generating up to 40% of their energy output as recoverable waste heat. Combined Heat and Power (CHP) systems maximise this efficiency by capturing and utilising the waste heat for district heating or industrial processes.

Can landfill gas systems expand as landfills grow?

Yes, systems are designed with provisions for landfill expansion and future gas management. Engineers plan integrated networks that can accommodate changing gas production rates and additional extraction points as waste deposits increase.

[First published on 28 November 2012. Updated August 2025.]

Landfill Gas Extraction Well Design – An Introduction

It is important that all landfill gas extraction wells (also known as gas extraction boreholes) are designed carefully in accordance with best practice. In this article we have tried to identify the most important aspect of design. We also recommend the United Kingdom reader to consult the UK Environment Agency Publication, “Guidance on the Management […]

Best Practices in Odour Control Using Landfill Gas Extraction Systems

Landfill gas extraction systems effectively control odour by capturing and treating gases from decomposing waste. Proper system design, strategic well placement, and regular maintenance are crucial for minimizing fugitive emissions and odour complaints, with reductions of up to 85% achievable when these best practices are followed…

Landfill Gas to Energy – The Win-Win Energy Source It Makes Sense to Use

Landfill Gas to Energy is truly a no-brainer renewable energy source (not to waste!), and in this article we explain why this is a fact. Unlocking Energy from Waste: The Power of Landfill Gas-to-Energy The Ingenious Cycle of Waste to Watts Transforming landfill gas into energy is not just a sustainable choice; it's a smart […]

Landfill Methane Capture: The Global Warming Reduction “Quick Win” You've Never Heard Of

Concerned about the menacing effects of landfill gas on our environment? You're not alone, but it's not as bad as it might be where a landfill has a well-engineered Landfill Methane Capture system installed. In fact, we go so far as to say that landfill methane capture and utilisation is the global warming reduction “Quick […]